ngraving on flat materials like metal tags, wood boards, or acrylic sheets is straightforward. But when it comes to curved surfaces—like rings, أكواب, الأنابيب, or wine bottles—things get a little more complex. The good news? With the right tools and techniques, أنت تستطيع laser engrave cylindrical or curved objects with precision and confidence.

في هذا الدليل, we’ll walk you through everything you need to know about laser engraving curved surfaces, from rotary tools to material alignment, plus a deep dive into how ComMarker fiber and UV laser systems make it easier than ever.

Why Curved Surface Engraving Matters

Whether you’re personalizing a wedding ring, branding a stainless steel tumbler, or serializing aerospace parts, curved surfaces are everywhere. Customers increasingly expect custom, high-quality marks—regardless of surface shape.

Common curved items that benefit from laser engraving:

- مجوهرات (خواتم, bangles)

- Drinkware (wine bottles, القوارير, البهلوانات)

- Cylindrical metal parts (الأنابيب, fittings)

- Promotional items (أقلام, flashlights)

- الأجهزة والأدوات الطبية

The Problem with Curves: Focus and Distortion

Laser engraving relies on maintaining a fixed focal distance between the laser head and the material surface. On a flat surface, this is easy. On a curved surface, لكن:

- ال focus point constantly shifts as the curve rises and falls.

- Laser beam distortion can occur, especially on steep curves.

- Text and graphics can warp, if not properly mapped to the surface geometry.

That’s why specialized techniques and tools—like المرفقات الدوارة—are key.

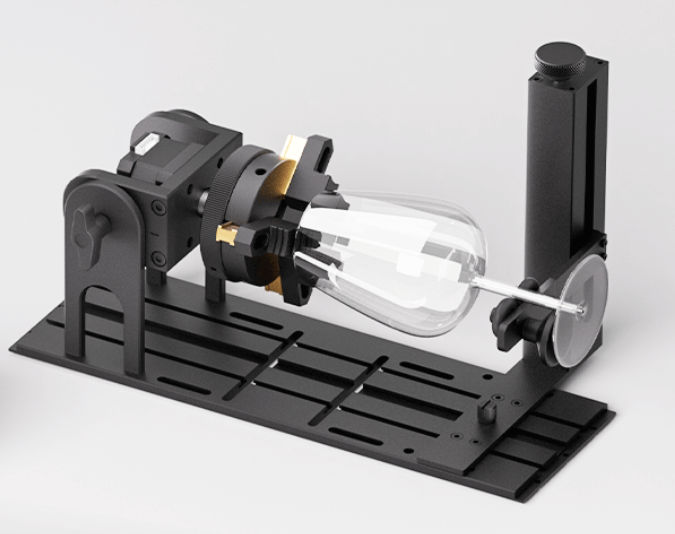

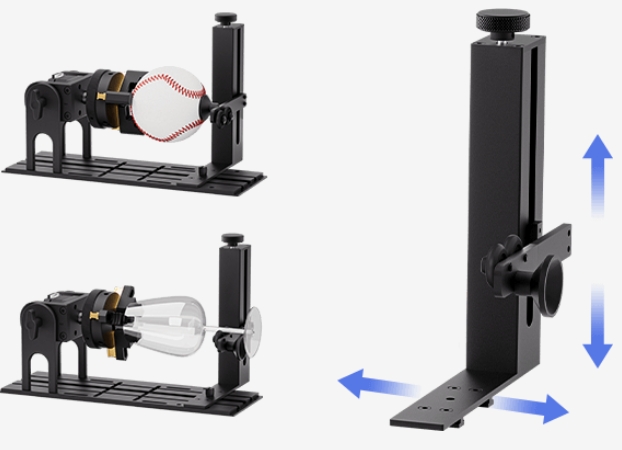

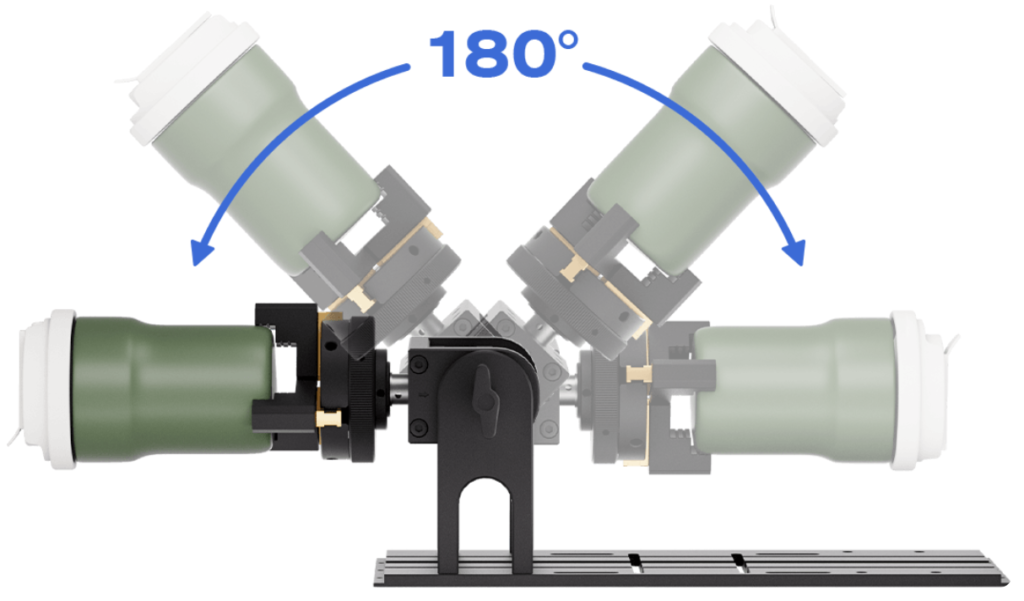

The Solution: Use a Rotary Axis Attachment

To handle cylindrical or rounded items, the most effective method is to use a rotary axis (or rotary chuck). This accessory rotates the object as the laser fires, keeping the beam at a consistent focus point across the entire circumference.

✅ Compatible with ComMarker Machines:

All ComMarker fiber and UV laser engravers, including the أومني 1 الأشعة فوق البنفسجية و تيتان 1 جي بي تي موبا, support rotary axis attachments. They’re plug-and-play with EZCad2 or LightBurn.

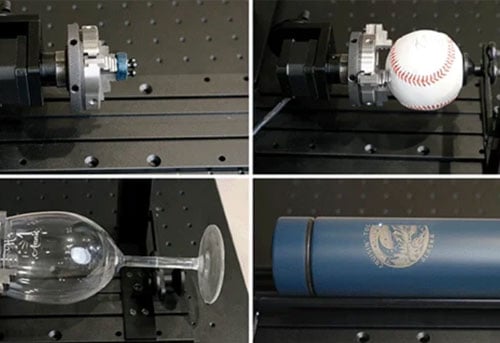

Types of rotary attachments:

- الأسطوانة الدوارة: Ideal for cups, البهلوانات, زجاجات, and tubes.

- Chuck Rotary: Perfect for rings, small cylinders, or conical objects.

- Jaw Rotaries: Best for complex or heavy cylindrical parts.

خطوة بخطوة: How to Laser Engrave Curved Surfaces with ComMarker

1. Prepare Your Laser Engraver

- Install your rotary axis and connect it to the appropriate control port.

- Select a lens size that fits your material (على سبيل المثال, 110×110mm for tight precision).

- يستخدم Lightburn أو ezcad2 to switch to rotary mode in settings.

2. تأمين المواد

- Use clamps, jaws, or friction rollers to stabilize the object. Ensure it rotates smoothly.

- For rings, align the inside of the ring perfectly within the focal plane.

- For cups or bottles, level the object to prevent wobble during rotation.

3. ركز الليزر

- يستخدم التركيز التلقائي (كومماركر أومني 1) or manually measure and adjust using the electric Z-axis.

- Some ComMarker models offer dual red-light focus pointers to help visualize the beam convergence point.

4. Configure Laser Parameters

This varies based on material and design complexity. Example settings for stainless steel:

| جلسة | فايبر ليزر (تيتان 1 – 30دبليو) | ليزر الأشعة فوق البنفسجية (أومني 1 – 10دبليو) |

|---|---|---|

| قوة | 80-100 ٪ | 50–70% |

| سرعة | 200–500 mm/s | 100–200 mm/s |

| تكرار | 20–60 kHz | 20-40 كيلو هرتز |

| الفاصل الزمني للخط | 0.02–0.05 mm | 0.03–0.05 mm |

| يمر | 1-3 | 2–4 |

✅ Use cross-hatching for high-density artwork.

✅ Enable “Enable Rotary” in LightBurn or EZCad to properly unwrap designs onto the curve.

5. Run a Dry Test

Before engraving:

- استخدم “frame” or “simulate” option to check pathing.

- Perform a low-power dry run (no beam) to detect misalignment or slip.

6. ابدأ النقش

Click “Start” and monitor the process. Ensure the object rotates consistently, and the laser remains in focus.

7. مرحلة ما بعد المعالجة

- Wipe down with isopropyl alcohol or mild cleaner to remove debris.

- للمعادن: consider applying a protective coating (على سبيل المثال, rust inhibitor).

- للزجاج: يستخدم Rust-Oleum white paint prep, then clean with thinner.

Tips for Engraving Specific Curved Materials

Glass Tumblers

- يستخدم ليزر الأشعة فوق البنفسجية (أومني 1) for clean, cold marking with no cracking.

- Spray surface with white matte paint for better contrast.

- Set speed: 200–300 mm/s, قوة: 30–40%, تكرار: 30 كيلو هرتز.

Metal Rings

- يستخدم ليزر الألياف (تيتان 1 or B6) with chuck rotary.

- Choose a high Q-pulse width (على سبيل المثال, 200–400ns) for smoother marks.

- Rotate slowly: ~30–50 mm/s.

Wine Bottles

- Rotate via roller rotary.

- Enable split marking with overlap: 0.1مم, split height: 1–3mm.

- Test for center point and start at the logo height.

Why Choose ComMarker for Curved Surface Engraving?

🔵 أومني 1 ماكينة النقش بالليزر فوق البنفسجية

- Cold-engraving safe for heat-sensitive materials

- التركيز التلقائي & فصل 1 حاوية السلامة

- Perfect for detailed artwork on glass, البلاستيك, والسيراميك

🟠 تيتان 1 ماكينة نقش ألياف الليزر MOPA

- Ideal for metal and industrial parts

- JPT MOPA source for color marking on stainless steel

- Modular lens and rotary support out of the box

ComMarker provides all the essential tools, مشتمل rotary kits, software support, and detailed tutorials, to help you get up and running on curved engraving—fast.

كومماركر أومني 1 حفارة الليزر

الجيل القادم من الليزر لفتح جميع المواد. تقنية النقش ZeroBurn™ أول حفارة ليزر بدقة 16K HD على مستوى العالم بسرعة 10000 مم/ثانية نظام النقش SpeedMax™ فتح جميع المواد باستخدام الليزر فوق البنفسجي بتقنية ColdFront™ الحرارية الرفع الكهربائي مع 2 عدسات اختيارية متوافقة مع نظام النقش الدوار EZCAD وLightBurn 360°

الأفكار النهائية

Laser engraving curved surfaces might seem like a challenge—but with the right setup, it’s a gateway to premium products and high-margin personalization. From stainless steel rings to glass drinkware, you can create durable, beautiful results that set your shop apart.

Ready to elevate your engraving game?

👉 Explore the كومماركر أومني 1 أو تيتان 1 فايبر ليزر, and equip your shop for next-level curved surface engraving.