من الصعب شهرة الزجاج. إنه لا يرحم, لا يمكن التنبؤ به - وغالبًا ما ينتهي في الشقوق, رقائق, or outright disaster. I learned that the hard way when one of my test panes exploded into what felt like a million glittering shards.

But that accident was just one part of a much bigger journey: 30,000+ individual UV laser test runs across multiple glass types.

What started as a quest for clean results quickly turned into a deep dive into laser behavior, physics, and tolerances. The good news? You don’t need to burn thousands of hours or panes—I’ve done the legwork for you.

أقل, I’ll walk you through the six most critical engraving variables, the exact settings that consistently delivered the best results, and a few powerful pro tips that can turn your average engraving into a showpiece.

Why UV Lasers Beat CO₂ for Glass Engraving

Both UV and CO₂ lasers can engrave glass, ولكن difference in quality is stark.

- ليزر CO₂ work by thermal fracturing. They deliver powerful infrared heat that causes micro-cracks and chips—acceptable for industrial uses, but rarely pretty.

- الأشعة فوق البنفسجية, by contrast, تعمل بطول موجة أقصر بكثير (355نانومتر), which allows them to interact with glass at a photochemical level. This means:

- Smoother, frosted finishes (similar to sandblasting)

- Sharper lines and better definition

- Reduced risk of fractures or thermal stress

ال 6 Essential UV Laser Settings for Glass

To get pro-level results, there are six key settings you need to understand and optimize:

- سرعة

- كيو نبض

- تكرار

- الفاصل الزمني للخط

- Number of Passes

- ركز

Let’s break down each one and see what the tests revealed.

1. سرعة

Speed controls how fast the laser moves across your design. You’d think faster is better—but on glass, slower usually wins.

- Block (Filled) Engravings:

Stick to 200–300 mm/s for a solid, consistent frost. - Outline Work:

Drop to 60–80 mm/s to ensure full marking along thinner paths. - Glass Type Variation:

- الزجاج المقسى: Handles speeds up to 400 مم/ثانية without losing fidelity.

- Standard Window Glass: Often requires 100–250 mm/s for optimal clarity.

نصيحة: Always test on a scrap first. Speed tolerance can vary based on your specific glass composition and any coatings.

2. كيو نبض

Think of كيو نبض as controlling the intensity of the energy burst delivered with each laser pulse.

- Lower values (1–2): Sharper, deeper engraves.

- Higher values (>5): Softer, more delicate touch.

🛠 Recommended Setting: Q-Pulse = 1 أو 2

These settings gave the most consistent and frosted results across all my test samples.

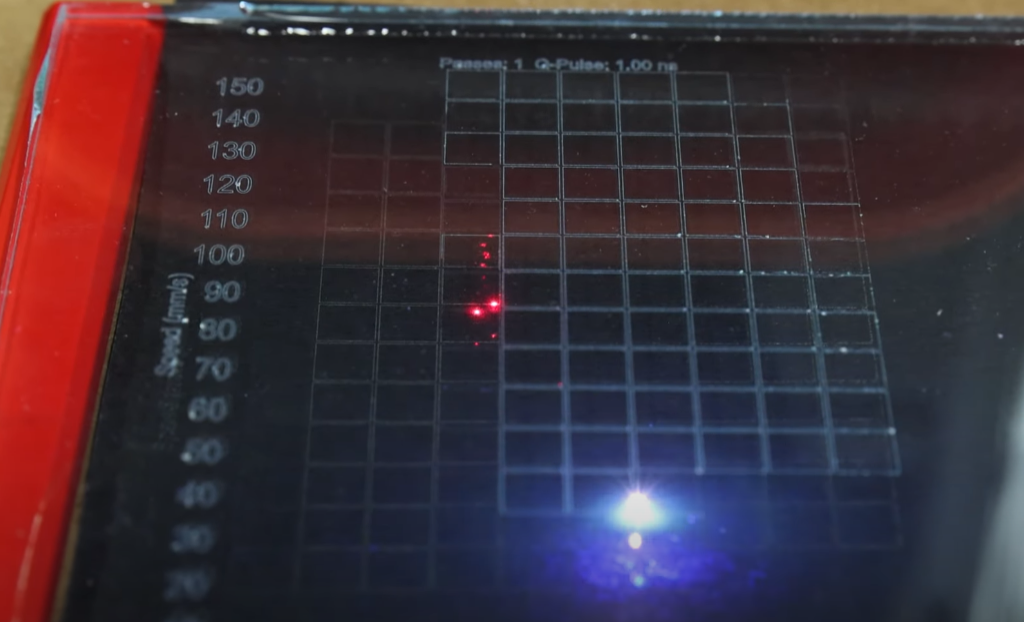

3. تكرار

This refers to how many pulses per second your laser delivers (measured in kHz). It directly affects how smooth the engraving appears.

- تردد منخفض (20–25 kHz): Strong but rough results—prone to “dotted” نَسِيج.

- التردد العالي (35-40 كيلو هرتز): Smooth tones, but risk of weak, patchy engraving.

Ideal Range: 30–35 kHz

This sweet spot balances power and finesse for clean, sandblasted finishes without overburning or skipping.

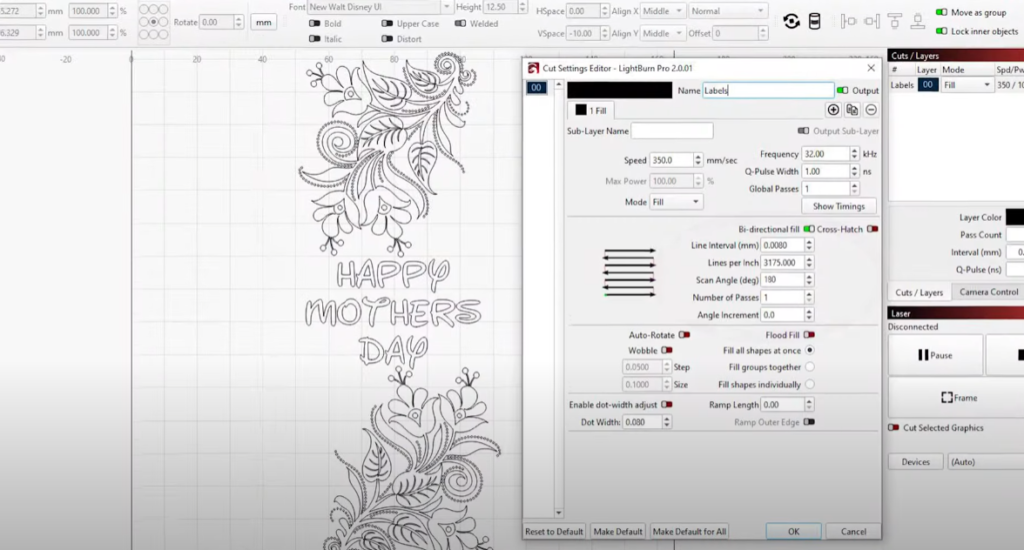

4. الفاصل الزمني للخط

This determines how tightly packed your scan lines are during a fill.

- Too Wide (>0.01 مم): Inconsistent coverage, banding, or patchiness.

- Too Tight (<0.002 مم): Beautiful results—but extremely slow jobs.

Best Range: 0.008–0.002 mm per line

Pro Trick:

في 0.001 مم, the engraving creates a raised, embossed effect with a solid white finish—almost like etched milk glass. لكن, it’s 4× slower than standard settings. Use for high-end projects.

5. Number of Passes

More passes = deeper engrave. But it doesn’t always mean better.

- 1 يمر: Sufficient for most applications if your other settings are dialed in.

- 2–3 Passes: Useful for deeper texture or touchable depth, but not necessary for clarity.

Caution: On tempered glass, too many passes can structurally weaken the pane and lead to breakage—like my poor, shattered test piece.

6. ركز

Getting your focus distance right is crucial.

- Optimal Focal Distance: Sharpest, cleanest engraving

- ±2 mm Offset: Still workable, but edges start to soften.

- ±4 mm or more: Expect patchy or faded results.

For Cylindrical Objects (Without a Rotary):

Set your focal point about 1 مم below the surface. This allows more vertical reach around the curve for better coverage.

Pro Tips to Save Time and Glass

1. Elevate Flat Pieces

Always lift flat glass slightly off the bed. If the beam passes through, it might engrave the underside of your piece—or worse, your machine bed.

Use small spacers, coins, or scrap acrylic.

2. Fix Mistakes Without Re-engraving the Whole Job

Made a tiny flaw or missed a section?

- Select the area in لايت بيرن

- Rotate the scan angle 180°

- Run that piece again

Since glass doesn’t darken with more passes, هذا refresh pass blends in seamlessly.

3. Account for Glass Warp

Large glass panes aren’t perfectly flat. في Lightburn, use the Z-offset tools أو split your design into segments with varied focal distances.

This helps maintain consistent quality edge-to-edge.

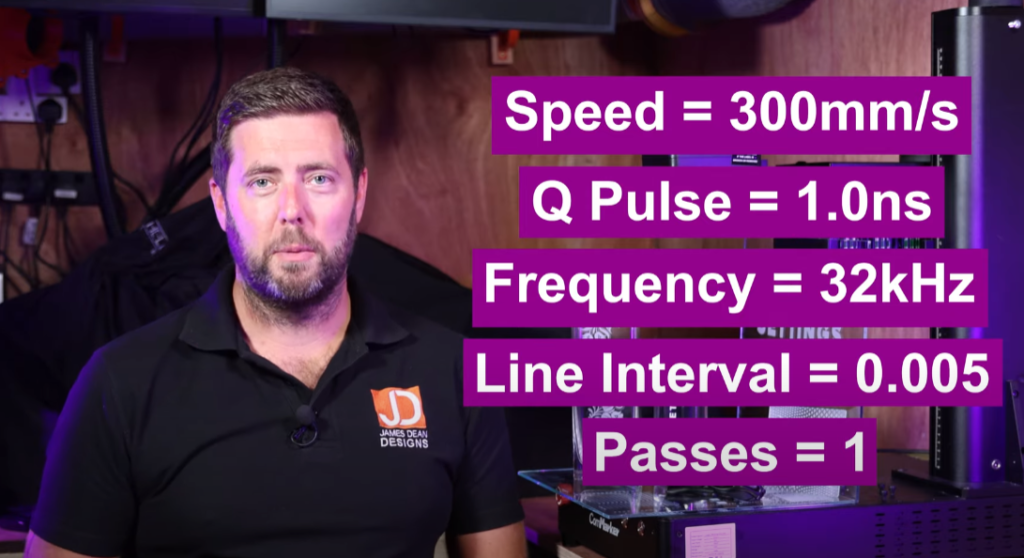

Cold-Start Settings (When You Only Get One Shot)

If I had zero time to test and only one attempt, these are the settings I’d go with:

| المعلمة | قيمة |

|---|---|

| سرعة | 300 مم/ثانية |

| كيو نبض | 1 |

| تكرار | 32 كيلو هرتز |

| الفاصل الزمني للخط | 0.005 مم |

| يمر | 1 |

| ركز | At exact focal point (±0 mm) |

كومماركر أومني 1 حفارة الليزر

الجيل القادم من الليزر لفتح جميع المواد. تقنية النقش ZeroBurn™ أول حفارة ليزر بدقة 16K HD على مستوى العالم بسرعة 10000 مم/ثانية نظام النقش SpeedMax™ فتح جميع المواد باستخدام الليزر فوق البنفسجي بتقنية ColdFront™ الحرارية الرفع الكهربائي مع 2 عدسات اختيارية متوافقة مع نظام النقش الدوار EZCAD وLightBurn 360°

Glass engraving doesn’t have to be a painful guessing game. With the right UV laser and properly tuned settings, you can produce clean, professional-quality work—even without specialized sandblasting gear or rotary attachments.

Every piece of shattered glass I went through was worth it if it saves you time, مادة, and frustration.

Interested in the UV laser I used for testing?

لقد استخدمت Omni One UV Laser, and you can find discount links and codes in the description if you’re thinking of adding one to your shop.