If you own a Lasergravierer, Sie wissen bereits, dass es ein leistungsstarkes Werkzeug zum Erstellen präziser Markierungen ist, Schnittdesigns, and personalizing a wide range of materials. But even the best laser machine can work smarter and faster with the right accessories.

Upgrading your laser station isn’t just about adding gadgets—it’s about improving Produktivität, Genauigkeit, und Sicherheit. Whether you’re running a small workshop, a side hustle, or a professional engraving business, these tools can help you take your work to the next level.

In diesem Ratgeber, Wir werden das erkunden essential accessories and tools every laser engraving setup should consider.

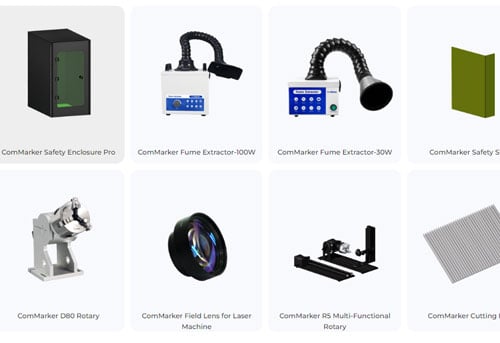

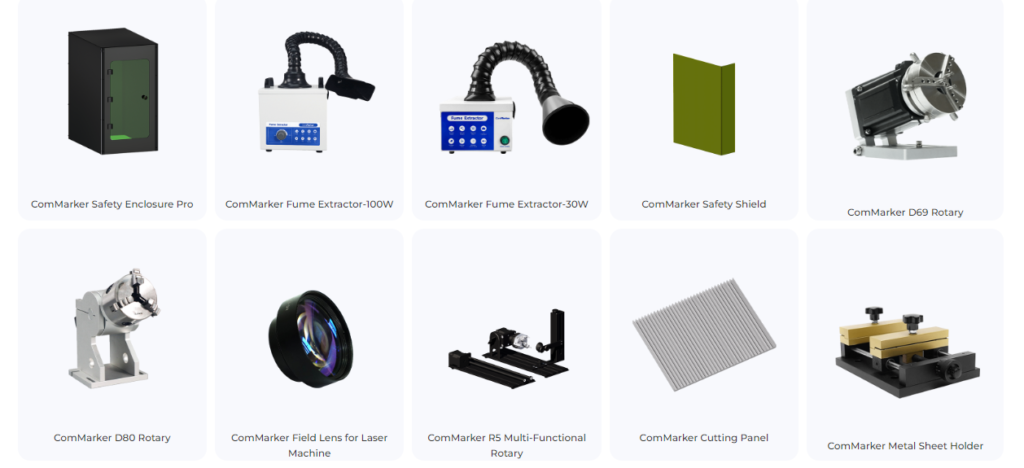

1. Precision Workholding: Jigs, Fixtures & Rotationswerkzeuge

A stable workpiece means a cleaner engraving. Investing in proper workholding tools can dramatically reduce mistakes and save setup time.

1.1 Custom Jigs & Fixtures

- Keep items perfectly aligned for batch production

- Essential for small products like coins, Stifte, or keychains

- Material tip: Use acrylic or wood to create reusable jigs

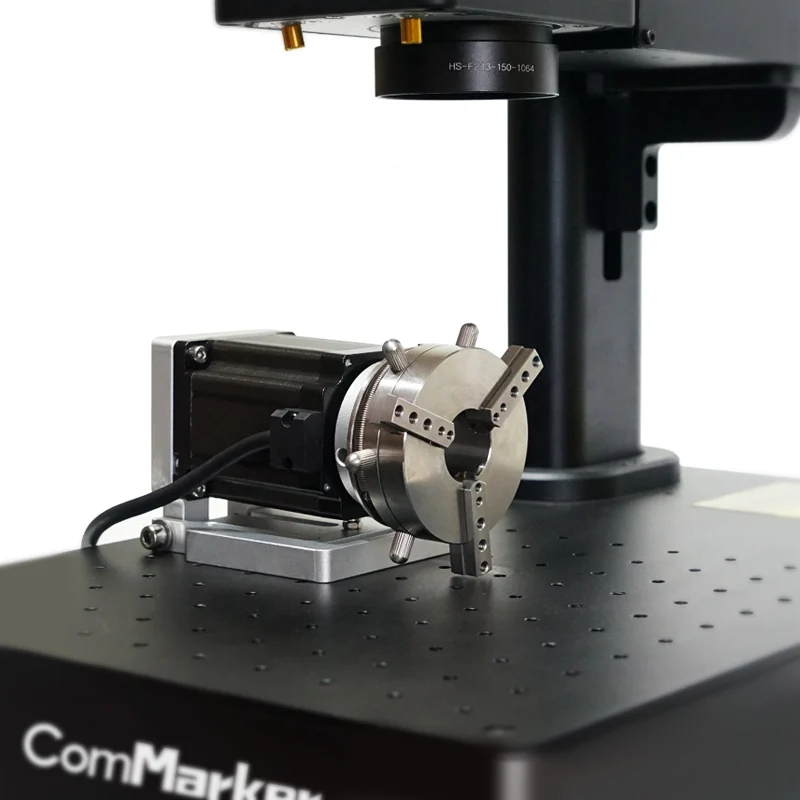

1.2 Rotary Attachments

- Allows engraving on cylindrical objects like tumblers, Tassen, und Ringe

- Available for Faserlasergravierer Und UV-Lasergravierer

- ComMarkers rotary axis is a popular add-on for Omni 1 UV and B4/B6 fiber models

💡 Für die Spitze: If you do high-volume production, consider quick-change fixtures to swap products in seconds.

2. Lens Upgrades & Field Lens Options

Dein Lasergravierer’s lens determines engraving area, Punktgröße, and detail level. Swapping lenses can optimize performance for different projects.

| Lens Size | Am besten für | Vorteile | Nachteile |

|---|---|---|---|

| 110×110 mm | Hohe Details, small items | Fine resolution | Small work area |

| 150×150 mm | General purpose | Balance of detail & area | Moderate trade-off |

| 300×300 mm | Large items, Beschilderung | Big coverage | Lower resolution |

💡 Empfehlung: Keep multiple field lenses and switch as needed. ComMarker’s Omni 1 UV supports quick lens changes for maximum flexibility.

3. Exhaust & Fume Extraction Systems

Laser engraving can produce fumes, especially when working with plastics, Holz, or coated metals.

- Fume Extractors: Pull harmful particles away from your workspace

- Inline Fans with Ducting: Direct fumes outside

- Activated Carbon Filters: Neutralize odors

Warum ist es wichtig: Clean air isn’t just about comfort—it’s about health and compliance with workplace safety regulations.

4. Design & Steuerungssoftware

While most laser engravers come with basic software, upgrading can unlock more advanced features.

- LightBurn: User-friendly with great vector editing tools

- EZCAD2 & EZCAD3: Standard for fiber laser engravers, supports complex parameter control

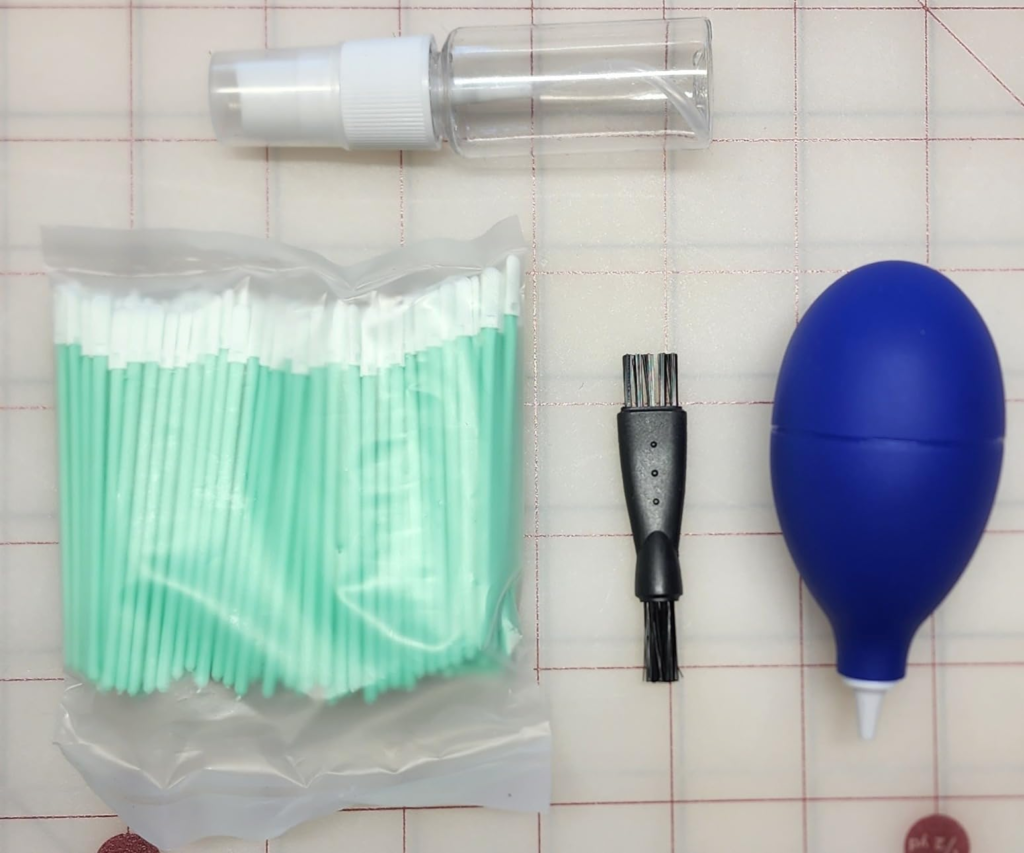

5. Wartung & Cleaning Tools

A clean machine lasts longer and works more consistently.

- Lens Cleaning Kits: Keep optics free of dust and debris

- Air Blowers: Remove residue from work surfaces

- Schmiermittel: Maintain moving parts in gantry-style CO₂ engravers

💡 Never touch your lens with bare hands—use proper microfiber cloths and cleaning solutions.

6. Safety Equipment

Laser safety should always come first.

- Lasersicherheitsbrille: Match the wavelength of your laser (z.B., 1064 nm for fiber, 355 nm for UV, 10,600 nm for CO₂)

- Enclosures & Shields: Contain laser light and debris

- Fire Extinguishers: Especially important for CO₂ laser cutting wood or acrylic

7. Workflow Optimization Tools

Speed up production and reduce errors with small workflow upgrades.

- Barcode & QR Code Scanners: Quickly load job files for batch work

- Work Lights: Improve visibility when aligning designs

- Bremssättel & Measuring Tools: Ensure accurate design placement

8. Recommended Starter Accessory Bundle

If you’re upgrading for the first time, here’s a balanced starter kit for most Lasergravierer Benutzer:

- 110 mm & 150 mm field lenses for versatility

- Rotary attachment for cylindrical engraving

- Fume extractor with carbon filter

- Lens cleaning kit

- Laser safety glasses

- LightBurn-Lizenz for better workflow

ComMarker Omni 1 Lasergravierer

Laser der nächsten Generation zur Freischaltung aller Materialien. ZeroBurn™-Graviertechnologie Weltweit erster 16K-HD-Lasergravierer 10.000 mm/s SpeedMax™-Graviersystem Entriegeln Sie alle Materialien mit UV-Laser ColdFront™-Thermotechnologie Elektrisches Heben mit 2 Optionale Objektive, die mit EZCAD und dem LightBurn 360°-Rotationsgravursystem kompatibel sind

Upgrading your laser station is less about flashy add-ons and more about investing in Präzision, Effizienz, und Sicherheit. Even small improvements—like a better jig or upgraded lens—can have a big impact on the quality of your work and the speed of your production.

If you’re ready to level up your engraving setup, consider pairing your Lasergravierer with the right accessories. Whether you’re using a ComMarker Omni 1 UV for ultra-fine detail work or a B6 MOPA Fiber for high-speed metal engraving, the right tools will make all the difference.