In the world of laser Engravers, Präzision ist alles. Ob Sie Text in Mikrogröße markieren, Gravieren komplizierter Muster, or working with delicate materials, the quality of your final product depends heavily on the laser source you choose. Over the past few years, UV-Laser have emerged as the preferred solution for applications that demand Feines Detail, saubere Kanten, and minimal heat damage.

But what makes UV lasers stand out compared to CO₂ or fiber lasers? Lassen Sie es uns aufschlüsseln.

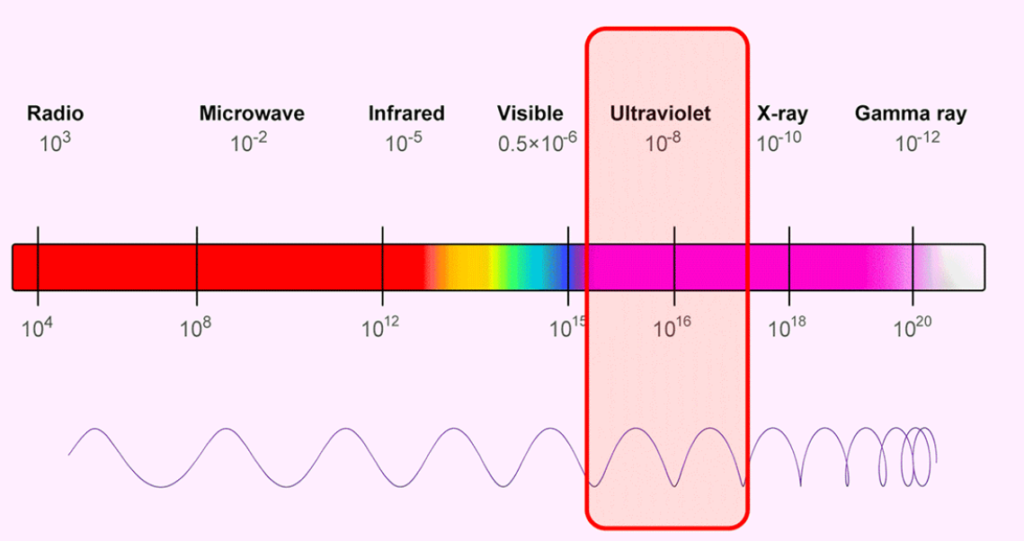

1. The Science Behind UV Lasers

Unlike CO₂ (10.6 μm) und Faserlaser (1064 nm), UV-Laser operate at a much shorter wavelength—typically 355 nm. This shorter wavelength interacts with materials differently, using a process called “cold marking” oder “cold processing”.

Key Characteristics:

- Minimaler Wärmezone (HAZ): Reduces burning, melting, oder sich verziehen

- Higher Absorption Rate: Works well on materials that are transparent or reflective to other wavelengths

- Smaller Spot Size: Allows for extremely fine lines and intricate detail

💡 Beispiel: While a fiber laser might struggle to engrave clear acrylic without melting, a UV laser can produce a crisp, frosted finish with no cracks or burn marks.

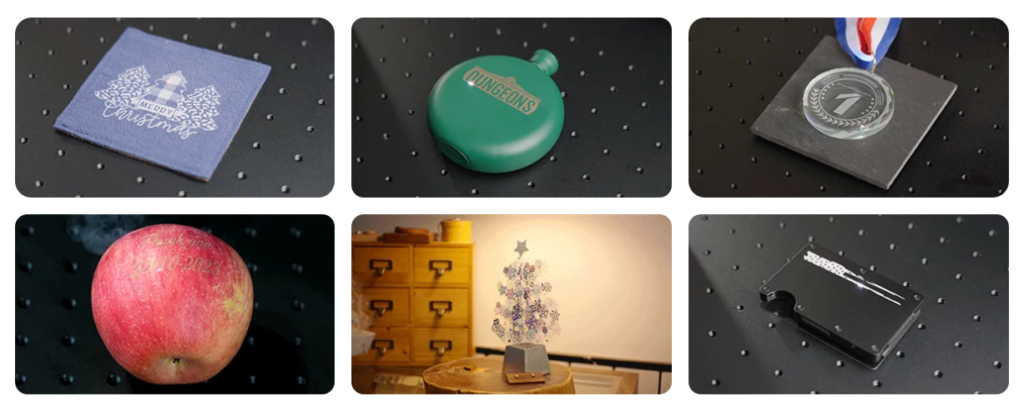

2. Materials That Benefit from UV Laser Engraving

One of the reasons UV lasers are gaining popularity is their breite Materialkompatibilität—especially for sensitive and specialty surfaces.

| Material | UV Laser Advantage | Example Applications |

|---|---|---|

| Kunststoffe (Abs, PC, PVC) | No melting or discoloration | Electronics housings, keycaps |

| Glas & Kristall | Fine, crack-free marking | Awards, Trinkgeschirr, luxury packaging |

| Keramik & Porcelain | Sauber, permanent marking | Mugs, Fliesen, medizinische Geräte |

| Metalle (Coated or Uncoated) | High-contrast marks | Medical tools, watch parts |

| Leder & Organics | Subtil, detaillierte Entwürfe | Luxury goods, branding logos |

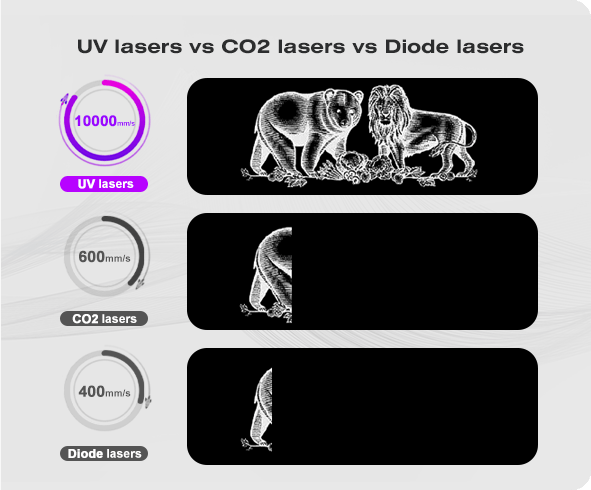

3. UV Lasers vs CO₂ and Fiber Lasers

Each laser type has its strengths, but UV lasers excel where fine detail and surface integrity matter most.

| Besonderheit | Co₂ Laser | Faserlaser | UV-Laser |

|---|---|---|---|

| Wellenlänge | 10.6 μm | 1064 nm | 355 nm |

| Beste Verwendung | Holz, Acryl, Leder | Metalle, einige Kunststoffe | Kunststoffe, Glas, Keramik, fine metals |

| Heat Damage | Hoch | Medium | Low |

| Detailstufe | Medium | Hoch | Very High |

| Material Vielseitigkeit | Medium | Hoch | Very High |

4. Why Manufacturers Are Choosing UV Lasers

4.1 Elektronik-Industrie

- Marking micro-components without damaging circuitry

- QR-Codes, Seriennummer, and micro text

4.2 Medical Device Industry

- Permanent marks that withstand sterilization

- Meets strict regulatory requirements for identification

4.3 Luxusgüter & Branding

- Ultra-precise logos on watches, Stifte, und Schmuck

- Subtil, non-intrusive markings for high-end appeal

5. Der ComMarker Omni 1 UV Advantage

When it comes to professional UV laser engraving, ComMarker Omni 1 UV is a standout choice.

- 355 nm Wellenlänge for superior fine detail work

- Multiple lens options (110×110 mm, 150×150 mm) for flexibility

- Perfect for plastics, Glas, Keramik, Beschichtete Metalle, und mehr

- Compact design ideal for small workshops and professional studios

💡 Für die Spitze: If you regularly work with mixed materials, consider pairing your UV-Lasergravierer with a rotary attachment for cylindrical items like bottles and mugs.

6. Zukünftige Trends: Why UV Lasers Will Keep Growing

Market demand for UV lasers is expected to rise sharply due to:

- Growth in microelectronics Und medizinische Geräte

- Increasing demand for Anpassung Und Personalisierung

- Stricter quality standards in manufacturing

Tatsächlich, industry reports project the UV laser segment to grow at über 8% CAGR in the next five years, outpacing CO₂ and fiber laser growth rates in certain sectors.

ComMarker Omni 1 Lasergravierer

Laser der nächsten Generation zur Freischaltung aller Materialien. ZeroBurn™-Graviertechnologie Weltweit erster 16K-HD-Lasergravierer 10.000 mm/s SpeedMax™-Graviersystem Entriegeln Sie alle Materialien mit UV-Laser ColdFront™-Thermotechnologie Elektrisches Heben mit 2 Optionale Objektive, die mit EZCAD und dem LightBurn 360°-Rotationsgravursystem kompatibel sind

If your projects require razor-sharp detail, minimal heat impact, and high material versatility, UV lasers are hard to beat. From delicate plastics to brittle glass, they deliver consistent, professional results that other laser types simply can’t match.

Whether you’re a DIY maker, Kleinunternehmer, or industrial manufacturer, upgrading to a UV-Lasergravierer like the ComMarker Omni 1 can open new possibilities for creativity and precision.