Le ComMarker Omni 1 is not your average desktop graveur laser. With a pulsed 355 nm UV laser, sub-25 nanosecond pulse widths, and swappable F-Theta lenses, it enters a new class of photonic precision. But what makes it different—and why would anyone choose this over a higher-powered 60W infrared fiber system?

Let’s take a look under the hood, at the beam, and deep into the glass.

UV vs IR: Why Wavelengths Matter

Infrared lasers (like fiber and MOPA) dominate in general purpose engraving: les métaux, marquage de couleur, deep cutting. But UV lasers, with their shorter wavelength, open doors to materials that are transparent to IR—like plastics, bois, verre, or PCBs.

UV’s shorter wavelength:

- Enables photochemical ablation rather than thermal burning

- Creates extremely small spot sizes for high DPI and clean micro-cuts

- Allows for sub-surface engraving in transparent materials

Résultat: Less heat, more control.

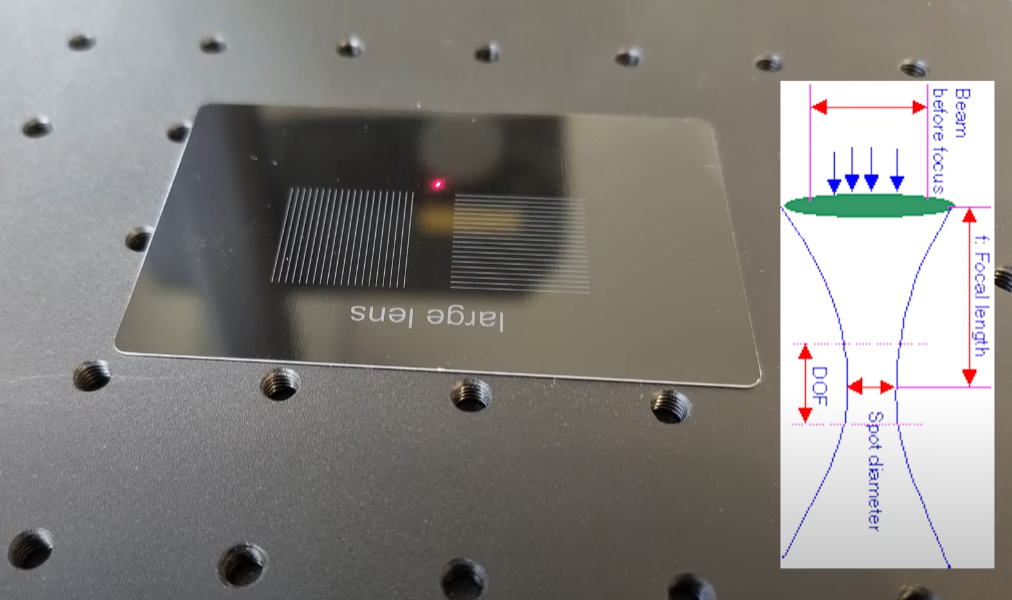

Optical Precision – The Truth About Spot Sizes

L'Omni 1 includes two F-Theta lenses:

- 70×70 mm lens – Shorter focal length, smaller spot size

- 150×150 mm lens – Larger working area, but lower resolution

While theory suggests sub-40μm spot sizes, real-world measurements yielded:

- ~53 μm with the large lens

- ~40 μm with the small lens (with fine-tuning)

For comparison: CO₂ lasers typically operate in the 100–200 μm range.

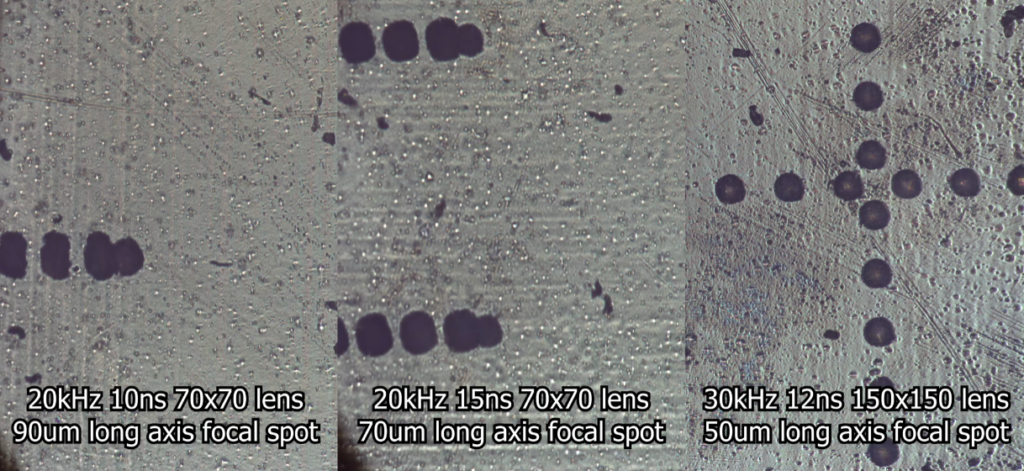

Pulse Widths and Beam Quality – Why It Matters

L'Omni 1 allows users to dial in fréquence (kHz) et durée de pouls (ns):

- Best results (roundest beam profile): 30 kHz / 12 ns

- Too short or too long disrupts beam symmetry (TEM00 degrades)

Changing pulse parameters dramatically affects:

- Beam shape

- Focus accuracy

- Energy delivery per impulse

This matters especially for glass work, PCB micromachining, et surface coatings.

Application Highlights

Here’s where this UV laser shines:

| Matériel | Résultat |

|---|---|

| Plastiques | Crisp white marks, no melting or charring |

| Bois | Faire le ménage, micro-thin cuts with minimal burn |

| Verre | Can embed 3D models à l'intérieur the glass |

| PCB | Micro-etch traces with <100μm precision |

| Textiles | Surface bleaching or engraving without damage |

| Silicium / ICs | Selective removal of epoxy molding |

Note: Always use proper dust extraction. UV glass cutting releases hazardous micro-particles.

Inside the Omni 1 – A Technical Teardown

Control and Optics:

- JCZ controller card

- True Galvo mirrors

- Motorized Z-axis (on newer models)

- Logiciel: LightBurn (limited for automation), or open-source Balor

Laser Module:

- DPSS laser with Nd:YAG crystal

- Q-switch driver for nanosecond-scale gating

- Tripled frequency via harmonic generation to 355 nm

- Thermoelectric cooling throughout

- Accessible pump diode (replaceable)

⚠️ Tip: Beam parameters affect thermal lensing in crystals—keep pulse energy consistent.

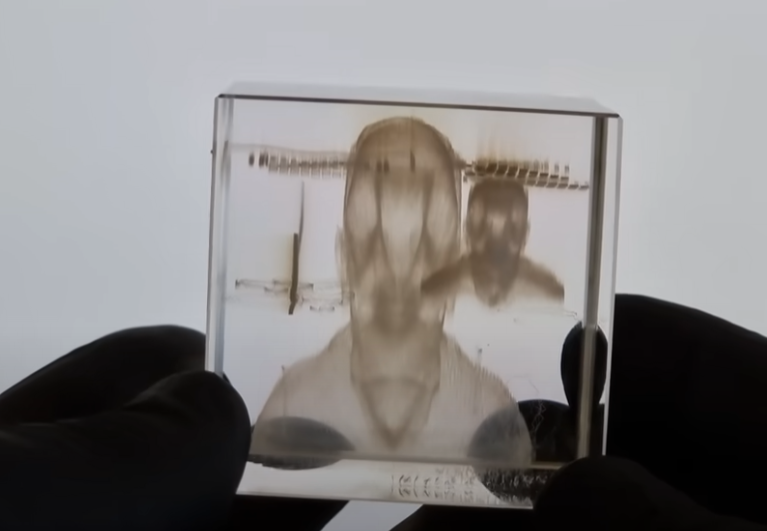

Nerd Feature: 3D Models Embedded in Glass

By compensating Z-height for glass’s refractive index, l'Omni 1 peut graver 3D voxels at varying depths inside a cube. This opens up:

- Microfluidic devices

- Embedded art

- Secure 3D data markers

- Experimental optics and light-guiding structures

Requires:

- G-code slicing of 3D models

- Python scripting (via Balor CLI)

- Fine-tuned pulse parameters (par exemple., 38kHz / 12ns)

Final Verdict

Avantages:

✅ Unmatched versatility across exotic materials

✅ Sharp, minimal heat cuts and marks

✅ Compact yet hackable design

✅ Perfect for PCBs, glasswork, and coatings

Les inconvénients:

❌ Slow for deep cuts

❌ Manual calibration can be tricky

❌ Safety concerns – fully open-frame design

Who Is This For?

Le ComMarker Omni 1 isn’t for mass production or brute-force cutting. But for:

- Engineers

- Scientists

- Engraving artists

- Experimental makers

- Micro-manufacturers

…it’s a precision tool that unlocks things no other graveur laser in its price range can do.

ComMarker Omni 1 Graveur laser

Laser de nouvelle génération pour débloquer tous les matériaux. Technologie de gravure ZeroBurn™ Le premier graveur laser HD 16K au monde Système de gravure SpeedMax™ 10 000 mm/s Déverrouillez tous les matériaux avec le laser UV Technologie thermique ColdFront™ Levage électrique avec 2 Objectifs en option compatibles avec le système de gravure rotative EZCAD et LightBurn à 360°

Want One?

Découvrez le ComMarker Omni 1 and stay tuned for more advanced guides on:

- Focus calibration

- Advanced PCB prototyping

- Sub-surface glass modeling