Le Omni 1 Graveur laser UV brings a new dimension to wood engraving. Designed for professionals seeking precision and high-definition results, it outshines CO2 lasers in several key areas.

Key Features of Omni 1

- Laser Spot Size: L'Omni 1 boasts a laser spot size of 0.0019millimètre, delivering unparalleled engraving detail.

- SpeedMax™ Technology: Achieves speeds up to 10,000 mm/s, enabling faster processing for intricate designs.

- Technologie thermique ColdFront™: Minimizes heat impact, preserving the natural color and texture of wood.

- Polyvalence: Grave sur une large gamme de matériaux, including hardwood, softwood, and even composite woods.

Gravure sur bois: Omni 1 Laser UV VS. Laser CO2

Précision et détail

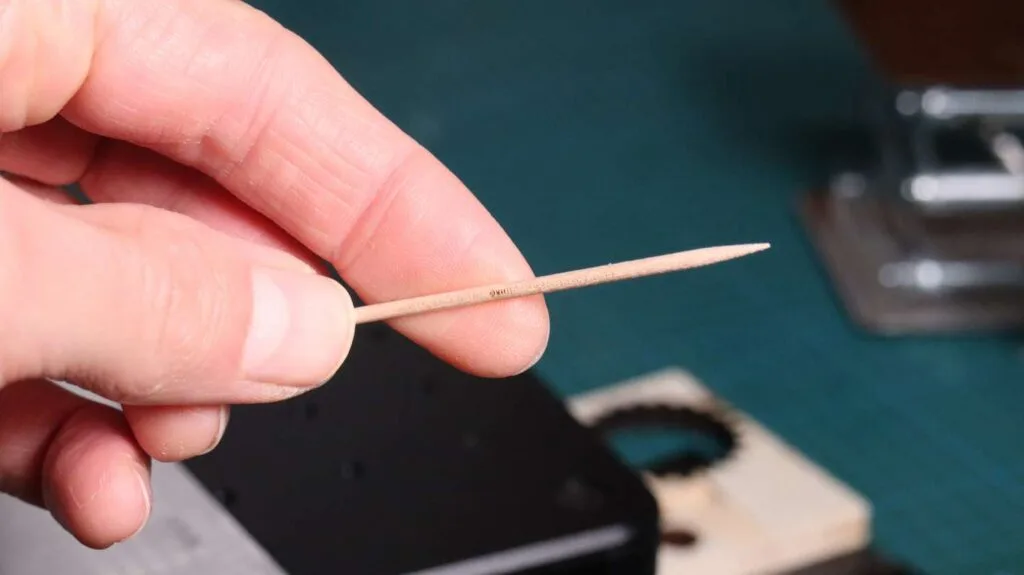

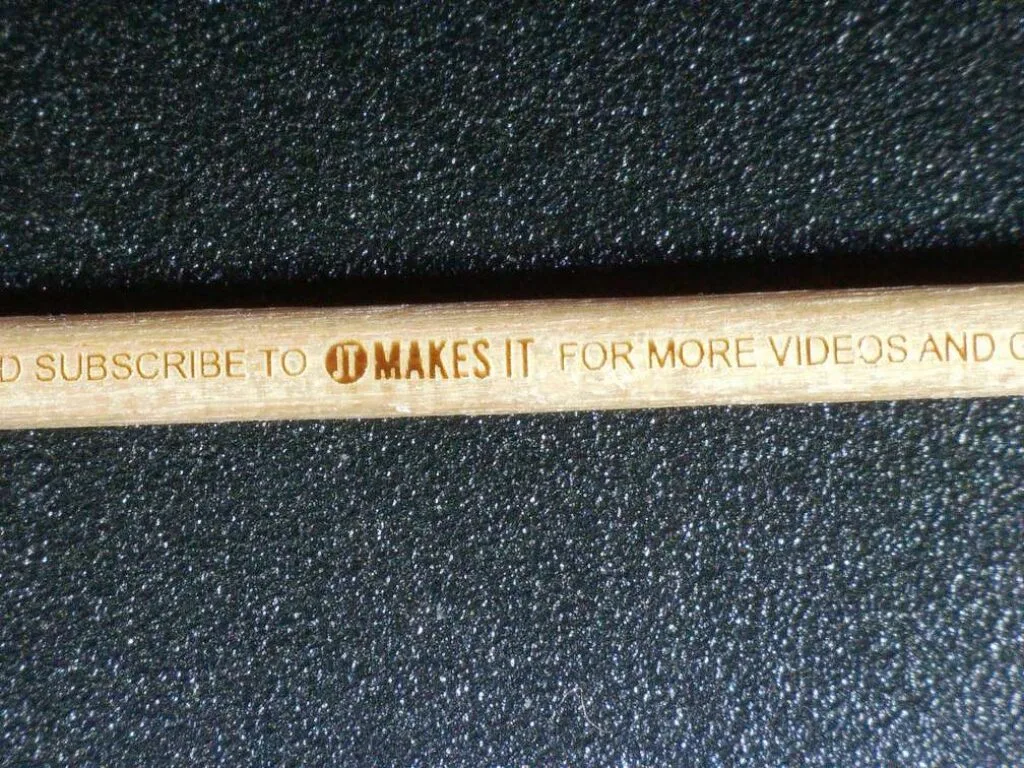

- Omni 1 Laser UV: The finer spot size and higher resolution allow for precise, high-definition engraving. This makes it ideal for fine art, conceptions détaillées, and engraving small fonts.

- Laser CO2: While effective for general engraving, its larger beam size limits the level of detail achievable, especially on intricate designs.

Exemple: When engraving a fine-grain wood like maple, l'Omni 1 can produce ultra-sharp text and patterns, whereas a CO2 laser might struggle to achieve the same clarity without over-burning.

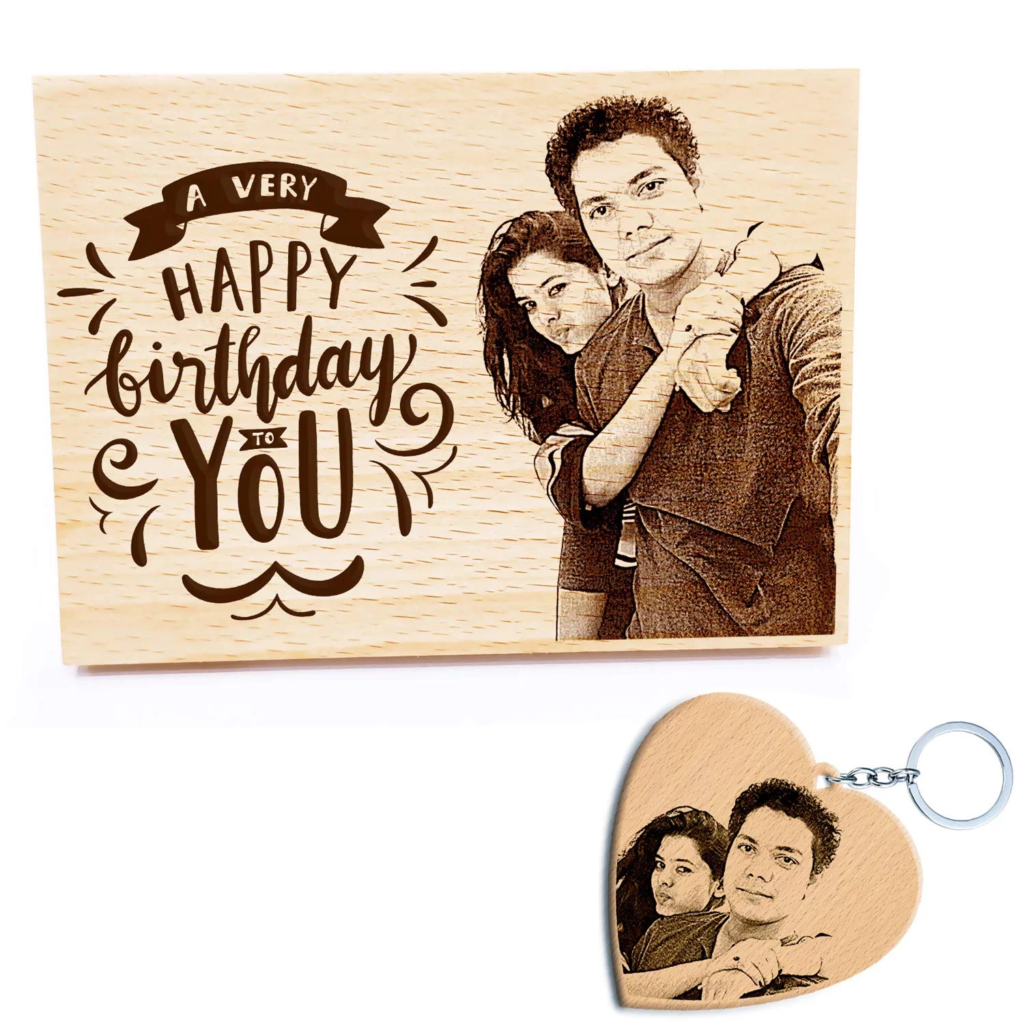

Heat Impact and Material Preservation

- Omni 1 Laser UV: The ColdFront™ technology ensures that the laser’s heat impact is minimal, preventing warping or discoloration of delicate woods like balsa or birch.

- Laser CO2: Produces more heat during engraving, which can result in scorch marks ou burned edges, especially on softwoods.

Exemple: For light-colored woods, such as pine or basswood, l'Omni 1 preserves the natural color without leaving burn marks, unlike CO2 lasers that may require post-processing to clean up.

Rapidité et efficacité

- Omni 1 Laser UV: Equipped with SpeedMax™ technology, it can engrave complex designs at high speeds without compromising precision. This is especially beneficial for large-scale projects.

- Laser CO2: While capable of high-speed engraving, the precision may decrease at higher speeds, and additional time is often needed for material preparation or post-processing.

Versatility with Wood Types

- Omni 1 Laser UV: Excels in engraving various wood types, from dense hardwoods like oak and walnut to delicate softwoods. The minimal thermal effect makes it suitable for engineered woods and even laminated surfaces.

- Laser CO2: Effective for most wood types but may struggle with materials like MDF or plywood due to inconsistent density and potential overheating.

Practical Applications: Omni 1 UV Laser in Wood Engraving

High-End Woodworking

L'Omni 1 is perfect for creating intricate designs on premium wood products, tel que custom furniture inlays, boîtes à bijoux, and decorative panels.

Custom Gift Engraving

For engraving names, logos, or detailed patterns on wooden gifts, l'Omni 1 ensures clean and professional results, even on challenging surfaces like curved or irregular wood pieces.

Fine Art and Restoration Projects

The precision of the Omni 1 allows artists and restorers to work on detailed wood carvings, sculptures, and heritage pieces without damaging the material.

Considérations de coûts et ROI

While UV lasers like the Omni 1 typically have a higher initial cost compared to CO2 lasers, the investment pays off through:

- Reduced Post-Processing: Minimal cleanup required, saving time and effort.

- Higher Quality Output: Attracts premium clients willing to pay for superior craftsmanship.

- Material Savings: Less waste due to precise engraving and cutting.

Omni 1 or CO2?

Choisir entre le Omni 1 Graveur laser UV and a CO2 laser depends on your specific needs as a professional engraver:

- Choose Omni 1 if you prioritize précision, minimal thermal effect, et polyvalence across wood types.

- Choose CO2 Laser if you require cost-effective solutions for bulk cutting and general engraving on organic materials.

Finalement, le Omni 1 Graveur laser UV redefines what’s possible in wood engraving, making it the top choice for professionals seeking to elevate their craft.