Yes—you absolutely can use a incisore laser to engrave plastic, and it’s one of the most versatile materials you can work with. Whether you’re customizing phone cases, creating branded nameplates, or designing unique accessories, plastic laser engraving offers endless creative potential. From hobby crafters to small business owners, more people are turning to incisori laser for personalized plastic projects—and for good reason.

In questa guida, we’ll walk you through what types of plastic you can safely engrave, how to choose the right laser engraver, best practices for setup and safety, and project ideas that will get you excited to hit that “Start Engrave” button.

What Is Plastic Laser Engraving?

Plastic laser engraving is the process of using a high-intensity laser beam to etch patterns, testo, or designs onto the surface of plastic materials. Unlike mechanical engraving, laser engraving is contactless, which makes it ideal for delicate or thin plastics that could be damaged by traditional tools.

Usando un incisore laser, you can achieve:

- Crisp lettering and barcodes

- Custom logos

- Fine line artwork

- Even full grayscale images with the right settings

The laser’s settings—speed, energia, frequenza, and focus—can be adjusted based on the type of plastic and the level of detail you want to achieve.

What Types of Plastic Can You Laser Engrave?

Here are some plastics commonly used for laser engraving:

| Plastic Type | Engraving Suitability | Note |

|---|---|---|

| Acrilico (PMMA) | ✅ Excellent | Clean edges, great for signage |

| addominali | ✅ Good | Watch for melting or warping |

| Policarbonato (pc) | ⚠️ Limited | May discolor; test first |

| Polietilene (PE) | ⚠️ Limited | Soft surface, prone to distortion |

| PVC | ❌ Avoid | Releases toxic chlorine gas |

| ANIMALE DOMESTICO (Poliestere) | ✅ Good | Thin sheets engrave well |

| Delrin (Acetal) | ✅ Excellent | Crisp results, ideal for industrial parts |

| HDPE / LDPE | ⚠️ Limited | May melt or smoke excessively |

💡 Per la punta: Always verify if your plastic is laser-safe. Avoid PVC and materials with unknown coatings. If unsure, consult the manufacturer or test a small piece first.

Choosing the Right Laser Engraver for Plastic Projects

Different laser types work better with different plastics:

🟣 UV Laser Engraver – ComMarker OMNI 1

- Lunghezza d'onda: 355nm

- Perché funziona: UV lasers excel at low-heat marking, making them ideal for fine, burn-free engravings on plastic.

- Meglio per: Plastic nameplates, electronics housings, cosmetic packaging

👉 Explore the ComMarker OMNI 1 Laser UV

🔵 Fiber Laser Engraver – ComMarker B6 MOPA

- Lunghezza d'onda: 1064nm

- Perché funziona: Best for plastics with additives (like ABS or Delrin), and allows for grayscale or color marking depending on material.

- Meglio per: Industrial tags, pulsanti, electrical enclosures

👉 Check Out the B6 MOPA Fiber Laser

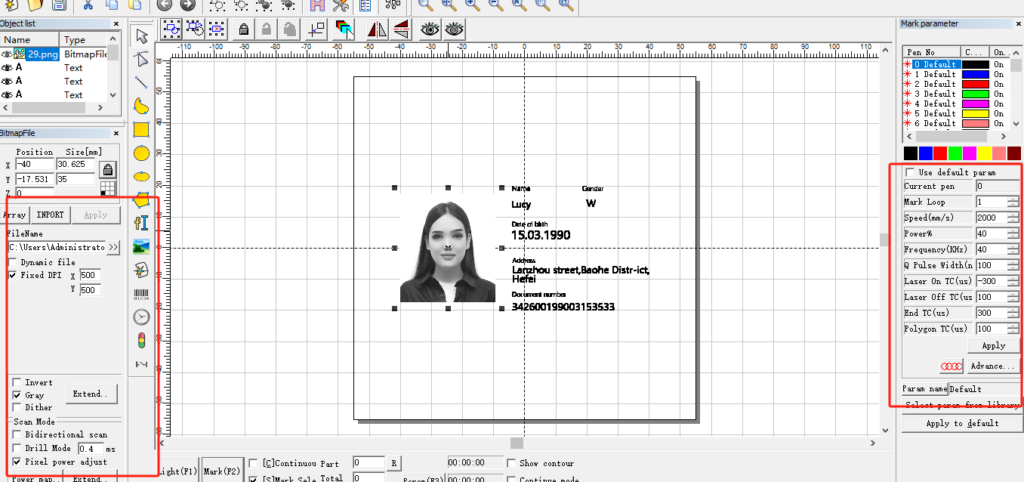

Passo dopo passo: How to Laser Engrave a Plastic Card

Here’s a beginner-friendly walkthrough to laser engrave a colored plastic card:

Fare un passo 1: Choose Your Plastic

Select a laser-safe plastic like acrylic or ABS. Use flat, smooth blanks for consistent results.

Fare un passo 2: Preparare il disegno

Use LightBurn or your favorite vector software to create your text or logo. Per i migliori risultati:

- Use high-contrast images

- Stick to vector graphics for cleaner lines

- Keep details sharp for small-scale projects

Fare un passo 3: Set Up the Machine

- Energia: Start at 20–40% for UV; 40–60% for fiber

- Velocità: 300–800 mm/s depending on plastic

- Messa a fuoco: Use auto-focus if available, or a spacing gauge

- Test run: Always run a preview pass before full engraving

Fare un passo 4: La sicurezza prima di tutto

Plastic engraving can release fumes. Always:

- Use air assist or external ventilation

- Wear protective eyewear (especially with UV lasers)

- Avoid burning unknown plastics

Fare un passo 5: Inizia l'incisione

Once settings are dialed in, engrave your first piece and make note of any adjustments needed for future jobs.

Creative Project Ideas with Plastic Laser Engraving

Laser engraving plastic isn’t just about labels. Try these fun and functional ideas:

- Custom Keychains – Add names, emojis, or business logos.

- Custodie per telefoni – Personalize designs for resale or gifting.

- Plastic Headphones – Engrave monograms or symbols.

- Storage Bins – Mark for office/home organization.

- AirPods Cases – Brand or customize stylishly.

- Coffee Pods – Add graphics for events or parties.

- Shampoo Bottles – Great for boutique packaging.

Sample Laser Settings for Popular Plastics

| Materiale | Velocità (mm/s) | Energia (%) | Frequenza (kHz) | Note |

|---|---|---|---|---|

| Acrilico | 600 | 30 | 20 | Use masking for clean edges |

| addominali | 300 | 40 | 30 | Lower speed to prevent melt |

| Delrin | 400 | 50 | 40 | Very crisp engraving lines |

| ANIMALE DOMESTICO | 500 | 25 | 25 | Great for nameplates |

ComMarker Omni 1 Incisore laser

Laser di nuova generazione per sbloccare tutti i materiali. Tecnologia di incisione ZeroBurn™ Il primo incisore laser HD 16K al mondo Sistema di incisione SpeedMax™ da 10.000 mm/s Sblocca tutto il materiale con il laser UV Tecnologia termica ColdFront™ Sollevamento elettrico con 2 Lenti opzionali compatibili con EZCAD e il sistema di incisione rotativa a 360° LightBurn

SÌ, You Can Laser Engrave Plastic!

UN incisore laser is one of the most powerful tools you can use to customize plastic. Whether you’re a DIYer, an Etsy seller, or a small business looking to expand your product line, laser engraving plastic gives you precision, flessibilità, and creativity.

So next time you wonder, can you laser engrave plastic?—you already know the answer.

👉 Ready to start? Choose the ComMarkerOMNI 1 for delicate, burn-free engraving or upgrade to the B6 MOPA Fiber Laser for color and speed.