If you’re thinking about laser printing on metal, the first question you’ll probably ask is: Can a laser engraver really handle that? The short answer—absolutely yes. Whether you’re working with stainless steel, alluminio, ottone, or titanium, a good incisore laser can mark, etch, or even deeply engrave metal with precision. In questa guida, we’ll break down what kind of laser you need, which metals work best, what specs actually matter, and how to choose a laser engraver that gives you professional results—without breaking the bank.

Why Laser Engraving Dominates Metal Marking

Laser engraving is the #1 method for permanent metal marking su acciaio inossidabile, alluminio, ottone, e titanio. Unlike mechanical engraving, it offers:

✅ Micro-Precision: 0.001mm spot size (per esempio., ComMarker Omni 1) for intricate serial numbers, loghi, or artwork.

✅ Zero Contact: No tool wear, burrs, or material distortion.

✅ Industrial Durability: Resists chemicals, Calore, e abrasione.

✅ Velocità: Engrave a custom knife in 60 seconds or 100 ID tags/hour.

4 Critical Factors When Choosing a Metal Laser Engraver

1. Tipo laser

| Tipo | Meglio per | Avoid If You Need… |

|---|---|---|

| Fibra | Raw metals (acciaio, Ti) | Under $2K budget |

| MOPA | Marcatura a colori su acciaio inossidabile | Basic etching only |

| UV | Coated metals, gioielleria | Incisione profonda (>0.2mm) |

2. Power Requirements

- 20W -50W: Marking/text (per esempio., numeri seriali)

- 60W–100W+: Incisione profonda (0.1–0.5mm) o taglio

- <5W UV: Surface marks on plated/coated metals

3. Dimensioni dell'area di lavoro

- 110× 110mm: Gioielleria, piccoli strumenti

- 300×300mm+: Armi da fuoco, industrial plates

4. Controllo del polso (MOPA Tech)

Essential forcolor marking stainless steel (black/gold/blue) by adjusting frequency and pulse width.

(Keywords: “fiber vs UV laser,” “MOPA metal marking,” “laser wattage guide”)

ComMarker Titano 1 Incisore laser a fibra JPT Mopa

Più forte che mai. Progettato per il sollevamento elettrico di superpotenza fino a 200 W con 2 Abilità di marcatura del colore delle lenti opzionali Super 3D Incisione & Capacità di taglio 15.000 mm/s Speedmax ™ Incisione 8K Accuratezza HD compatibile con EZCAD e Lightburn

Superiore 3 Laser Engravers for Metal (2025 Tests)

- ComMarker B6 MOPA (20W -50W)

- Meglio per: Small shops, color marking knives/tools

- Specifiche chiave: 0.01mm spot, 110×110mm area, portatile

- ComMarker Titano 1 (60W -200w)

- Meglio per: Deep engraving firearms/machinery parts

- Specifiche chiave: 3Incisione D, 6000velocità mm/s, 300×300mm area

- ComMarker Omni 1 UV (5W)

- Meglio per: Gioielleria, elettronica, metalli rivestiti

- Specifiche chiave: 0.0019mm spot, non-thermal process

Proven Laser Settings for Common Metals

Tested parameters forcrisp, consistent results:

| Metallo | Energia | Velocità | Freq. | Assistenza aerea? |

|---|---|---|---|---|

| Acciaio inossidabile | 80–100% | 300–500 | 30–60 | SÌ |

| Alluminio | 20–50% | 600–1000 | 20–30 | Opzionale |

| Ottone | 60–90% | 200–400 | 40–60 | SÌ |

| Titanio | 70–100% | 400–700 | 50–80 | SÌ |

⚠️Critical: Eseguire sempre afocus test (ramp method) before production. Material thickness affects beam convergence.

(Keywords: “laser settings for stainless steel,” “metal engraving parameters”)

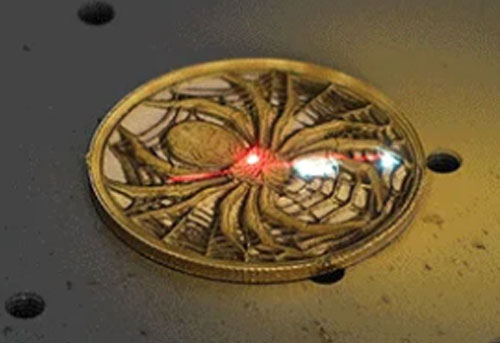

5 High-Profit Metal Engraving Applications

- Custom Knives/Tools: Loghi, ownership marks (50–100W fiber)

- Bicchieri & Drinkware: Full-wrap designs (MOPA for color)

- Gioielleria: Micro-engraving pendants/rings (Laser UV)

- Armi da fuoco: Compliance markings + personalizzazione (check ATF rules!)

- Aerospace ID Plates: Codici a barre, Seriali (laser a fibra)

4 Costly Mistakes to Avoid

- Using CO₂ on bare metal → Leaves faint/unreadable marks.

- Skipping fume extraction → Metal vapor is toxic (install exhaust + filter).

- Engraving coated metals too deep → Peeling/cracking (utilizzo <0.05mm depth).

- Guessing focus → Calibrate with a ramp test for sharpness.

The Verdict

SÌ, laser engravers excel with metal – butfiber/MOPA lasers are essential for professional results. For under $5K, models like theComMarker B6 deliver precision rivaling industrial machines.

🔥Hot Tip: Need deep engraving? Prioritizepulse energy over wattage. A 50W MOPA often outperforms 100W non-MOPA lasers.

Ready to Start?

→ Compare Metal Laser Engravers

FAQ Section (Schema-Rich)

Q: Can diode lasers engrave metal?

UN: Only with thermal spray coatings (per esempio., Cermark). Fiber/UV lasers are required for raw metal.

Q: How deep can a 50W laser engrave metal?

UN: 0.1–0.3mm on steel/brass (after 3–5 passes).

Q: Why does stainless steel turn black when engraved?

UN: MOPA lasers oxidize the surface – adjust pulse width for gold/blue effects.