Stainless steel engraving demands precision, durabilità, ed efficienza. While CO2 lasers have long been a go-to for many workshops, ILComMarkerOMNI 1 Incisore laser UV redefines what’s possible on metal surfaces—without the limitations of traditional CO2 systems. In this deep dive, we’ll explore the technical advantages of UV laser technology, share actionable setup tips, and reveal how to achieve flawless results on stainless steel.

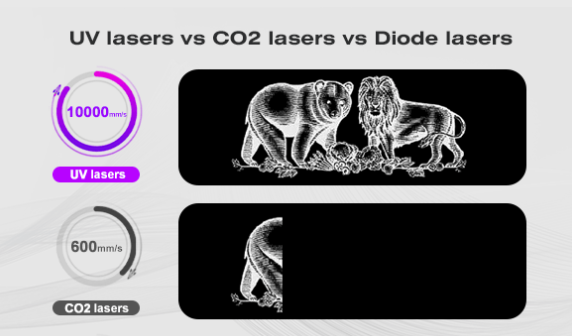

The Science Behind UV Lasers vs. CO2: Why OMNI 1 Wins

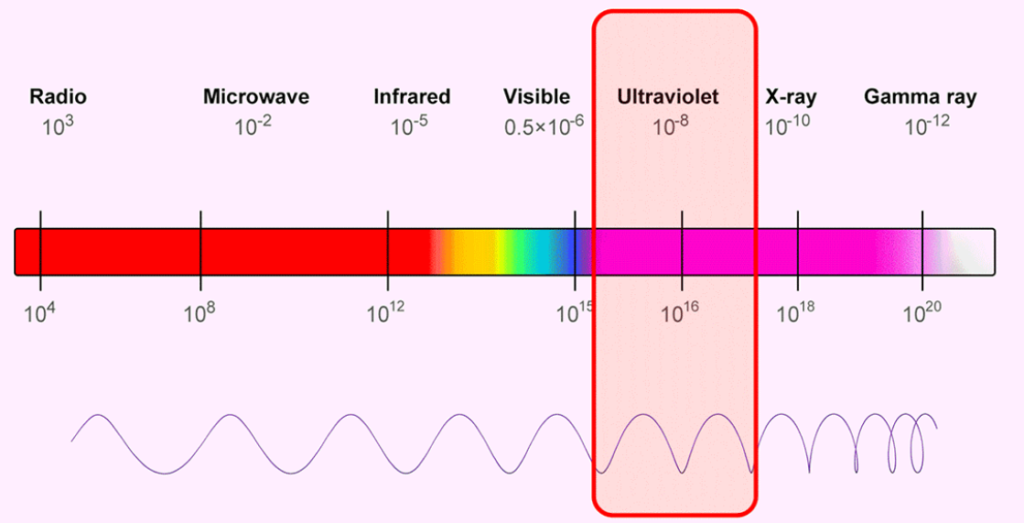

Laser a CO2 (10.6lunghezza d'onda μm) excel at engraving organic materials like wood or acrylic, but they struggle with metals. Here’s why the OMNI 1’sLaser UV (355lunghezza d'onda nm) dominates on stainless steel:

- Photon Energy Advantage

- UV photons pack 30x more energy per pulse than CO2 lasers, enabling direct interaction with metal surfaceswithout coating additives.

- Risultato: Croccante, oxidation-free marks that withstand abrasion and chemicals.

- Ultra-Fine Beam Focus

- The OMNI 1’s beam spot size can reach20µm (contro. CO2’s 250μm), allowing intricate details like 0.1mm fonts or micro QR codes.

- Per la punta: Pair this with ComMarker’sHigh-Precision Air Assist Kit to eliminate debris and maintain focus.

- Cold Marking Technology

- CO2 lasers melt the steel surface, causing thermal distortion and “halo” effects. L'OMNI 1 usiphotochemical ablation, vaporizing material at the molecular level.

- Proof: See the microscopic comparison below—OMNI 1 leaves smooth edges, while CO2 creates micro-cracks.

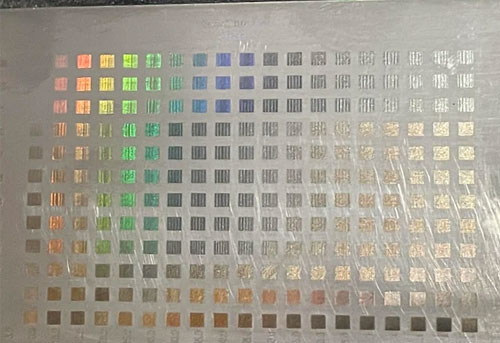

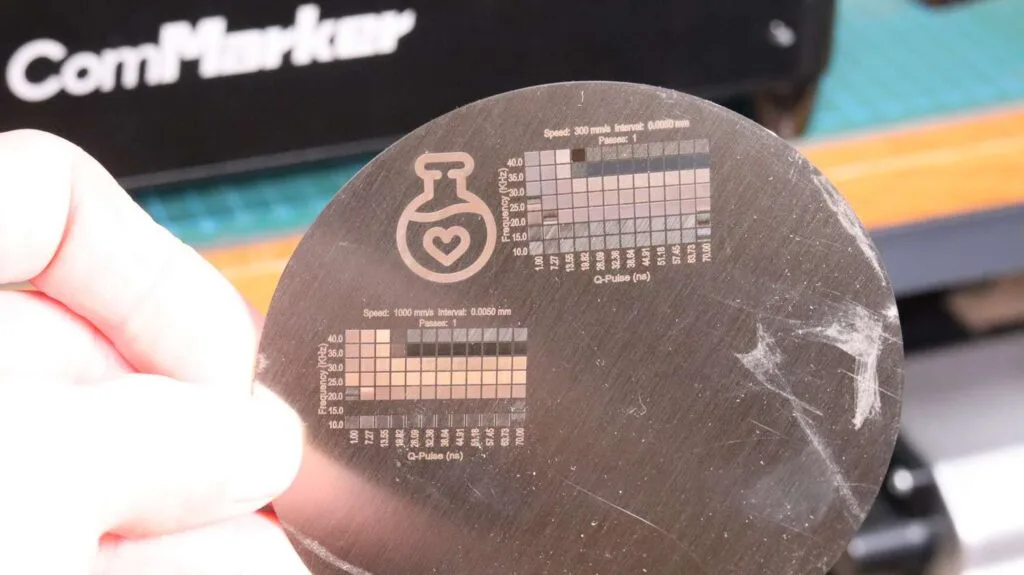

Optimizing OMNI 1 Settings for Stainless Steel

Maximize your machine’s potential with these tested parameters:

Basic Engraving (Black Annealed Mark)

| Parametro | Valore |

|---|---|

| Potenza del laser | 80% (30W model) |

| Velocità | 800mm/s |

| Frequenza | 50kHz |

| Passa | 1 |

| Focus Height | 2mm (utilizzo ComMarker Auto-Focus Gauge) |

Nota: For darker marks, increase frequency to 80kHz and reduce speed to 500mm/s.

Incisione profonda (0.2-0.5mm Depth)

| Parametro | Valore |

|---|---|

| Potenza del laser | 100% |

| Velocità | 300mm/s |

| Frequenza | 20kHz |

| Passa | 3-5 |

| Air Assist Pressure | 25 PSI (prevents slag buildup) |

⚠️ Critical: Always use the OMNI 1 Dedicated Exhaust System to remove toxic chromium particles.

Risoluzione dei problemi comuni

Problem 1: Faded or Inconsistent Marks

- Checklist:

- Clean the lens with ComMarker UV Lens Wipes. Dust reduces beam intensity.

- Verify focus height—misalignment is the #1 cause of blurry marks.

- Replace the air assist filter if airflow weakens.

Problem 2: Burn Marks or Discoloration

- Soluzione:

- Lower laser power to 70% and increase speed to 1000mm/s.

- Apply a thin layer of Laser Anti-Spatter Spray to protect the surface.

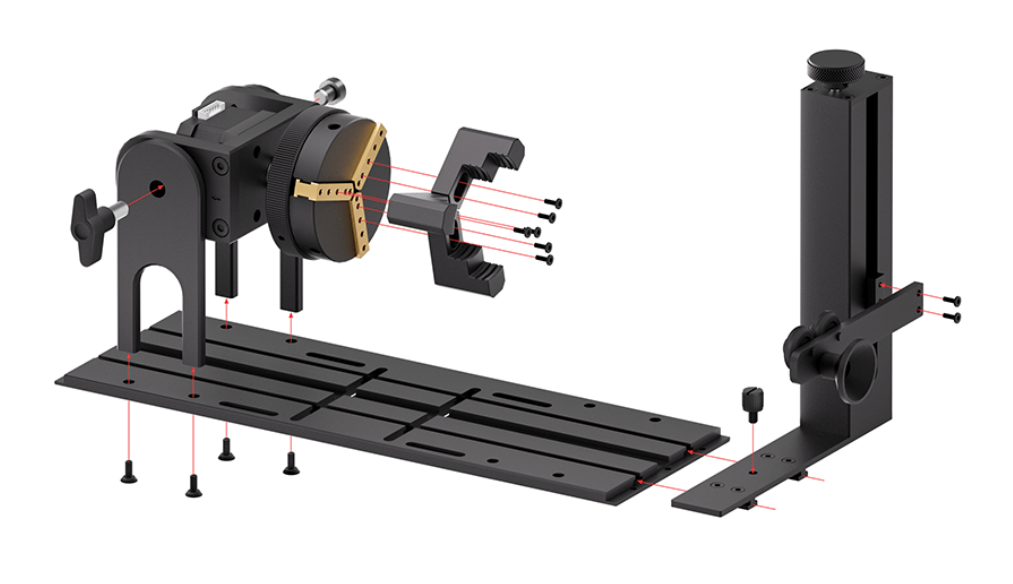

Real-World Case Study: Aerospace Part Marking

Sfida: A manufacturer needed to engrave 0.2mm-tall serial numbers on 316L stainless steel bolts. CO2 lasers failed to meet ISO/ASTM durability standards.

OMNI 1 Soluzione:

- Usato 20W OMNI 1 con Rotary Fixture Pro.

- Parametri: 65% energia, 1200mm/s, 60kHz.

- Risultato: Passed 500-hour salt spray tests with zero corrosion—saving $12k/year vs. outsourcing.

Why Choose OMNI 1 Over CO2?

| Factor | OMNI 1 Laser UV | Laser CO2 |

|---|---|---|

| Mark Quality | No heat distortion | Thermal halo common |

| Velocità | 2x faster on metals | Più lentamente, multi-pass needed |

| Operating Cost | $0.10/ora (no gas) | $0.30/ora (gas assist) |

| Preparazione del materiale | None required | Coatings mandatory |

ComMarker Omni 1 Incisore laser

Laser di nuova generazione per sbloccare tutti i materiali. Tecnologia di incisione ZeroBurn™ Il primo incisore laser HD 16K al mondo Sistema di incisione SpeedMax™ da 10.000 mm/s Sblocca tutto il materiale con il laser UV Tecnologia termica ColdFront™ Sollevamento elettrico con 2 Lenti opzionali compatibili con EZCAD e il sistema di incisione rotativa a 360° LightBurn

Ready to Upgrade?

L'OMNI 1 isn’t just a tool—it’s a stainless steel game-changer. Whether you’re crafting custom knives, etichette industriali, o dispositivi medici, this laser delivers lab-grade precision at workshop prices.

Explore Packages:

- OMNI 1 Basic Kit: Perfect for startups ($3,999).

- OMNI 1 Pro Workshop Bundle: Includes exhaust, rotary tool, and 1-year support ($4,639).