Buying a レーザー彫刻機 is an exciting investment, whether you’re a hobbyist, 中小企業経営者, or industrial user. But like any precision machine, your engraver needs proper maintenance to stay in top shape. Neglecting routine care can lead to blurry results, overheating, or even permanent damage to expensive components.

このガイドでは, we’ll show you exactly how to maintain your laser engraver for long-term performance, covering cleaning, 較正, software updates, and best practices for both CO₂ and fiber/UV systems.

Why Laser Engraver Maintenance Matters

あ レーザー彫刻機 works by directing a high-energy beam onto a material. Even minor dust buildup or misalignment can scatter the beam, reduce power, and damage the optics. Consistent maintenance ensures:

- Better engraving quality (sharper lines, deeper marks)

- Longer machine lifespan

- Reduced downtime and repair costs

- Safer operation

📌 Recommended Reading: 5 Mistakes to Avoid When Using a UV Laser Engraver

1. Keep the Optics Clean

Your engraver’s lenses and mirrors are the heart of the system. Any dust, smoke residue, or fingerprint smudge can block the beam.

- How to clean: Use lens wipes or dedicated optical cleaning fluid. Avoid paper towels, which can scratch.

- 頻度: After every heavy engraving session, or at least weekly.

- ヒントの場合: Always power off the machine before touching optics.

👉 Clean optics = stronger laser output and more consistent results.

2. Maintain the Work Surface

A cluttered or damaged work surface can throw off your focus.

- Honeycomb bed or grid table: Remove debris regularly.

- Alignment check: Use jigs or positioning tools to ensure consistency.

- Flatness: If you engrave wood or acrylic often, check for warping caused by heat.

- 📌 Recommended Reading: すべての初心者が持つべきレーザー彫刻アクセサリ

3. Inspect and Replace Filters & 換気

Laser engraving generates fumes, especially with wood, レザー, とプラスチック. Poor ventilation can affect both your health and your machine.

- Inline fans & ducts: Check for clogs or dust buildup.

- Fume extractor filters: Replace activated carbon filters as recommended by the manufacturer.

- Workspace airflow: Ensure proper ventilation in your engraving area.

4. Regularly Check Focus and Calibration

An improperly focused レーザー彫刻機 won’t cut or mark effectively.

- Manual focus tools: Use the provided focal stick or gauge.

- Auto-focus systems: Test for accuracy, especially after moving the machine.

- Calibration tests: Run a small grid test to check sharpness and consistency across the work area.

👉 A well-calibrated engraver saves you from wasted materials and rework.

5. Monitor Laser Source Health

Different engravers have different sources:

- CO₂ tubes: Typically last 1,500–3,000 hours. Power output drops over time — expect replacements.

- ファイバーレーザー: Lifespan often exceeds 100,000 hours with minimal decline.

- UVレーザー: Require less maintenance but still benefit from regular inspection.

👉 If engraving depth suddenly decreases, it may be time to service or replace the source.

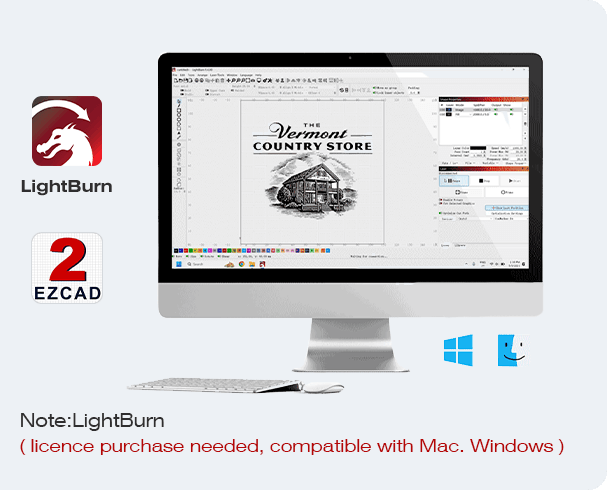

6. Keep Software and Firmware Updated

あなたの レーザー彫刻ソフト plays a huge role in performance.

- EZCAD, ライトバーン, or proprietary software: Check for updates.

- Firmware updates: Some engravers release patches that improve speed or accuracy.

- Backup settings: Save material libraries and parameter profiles regularly.

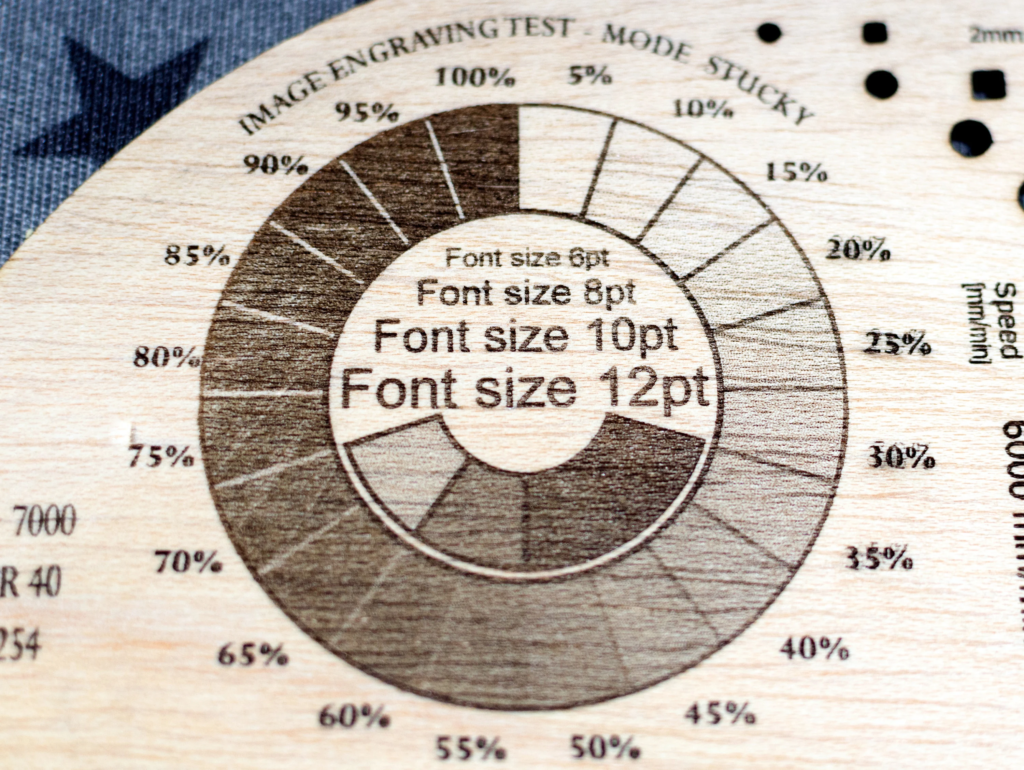

7. Run Preventive Test Engravings

Before starting a large project, run small tests. This ensures that:

- The focus is correct

- The design is positioned properly

- The engraving settings match your material

👉 This habit prevents costly errors on expensive blanks like stainless steel flasks or branded tumblers.

Pro Tips for Extending Laser Engraver Life

- Never run your laser at 100% power for long periods — it shortens tube life.

- Always test new materials with small samples first.

- Create a maintenance log (dates for cleaning, filter changes, software updates).

- Stock common spares: fuses, ベルト, and lens kits.

- Schedule annual professional servicing if your machine is business-critical.

コムマーカーオムニ 1 レーザー彫刻機

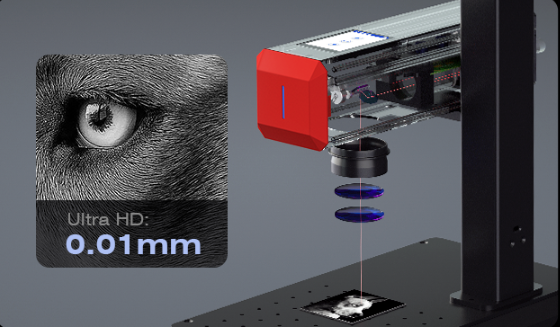

あらゆる素材を解き放つ次世代レーザー. ZeroBurn™ 彫刻テクノロジー 世界初の 16K HD レーザー彫刻機 10,000mm/s SpeedMax™ 彫刻システム UV レーザーですべての素材のロックを解除 ColdFront™ サーマルテクノロジー 電動リフティング 2 EZCADおよびLightBurn 360°回転彫刻システムと互換性のあるオプションのレンズ

あなたの レーザー彫刻機 is a precision tool — treat it like one. With consistent cleaning, 較正, and proper handling, you can dramatically extend its lifespan and enjoy sharper, more reliable results.

覚えて: a few minutes of preventive maintenance saves you hours of frustration (and hundreds of dollars in repairs).