Understanding How a UV Laser Engraver Works

ㅏ UV 레이저 조각사 uses short-wavelength ultraviolet light to mark materials with high precision and low heat. Unlike fiber or CO₂ engravers, UV systems are excellent for:

- Delicate materials like glass, 플라스틱, 가죽, 그리고 아크릴

- High-contrast markings on transparent or heat-sensitive surfaces

- Fine-detail projects 바코드와 같은, 로고, or text on electronics and medical devices

The cold processing of a UV 레이저 조각사 minimizes heat distortion, making it the ideal tool for intricate engraving tasks.

Why Choosing the Right Laser Engraver Matters

Not all 레이저 조각사 are created equal—especially when it comes to UV engraving. 정도, 제어, and safety features are key when working with delicate or expensive materials.

Choose a UV laser engraver with:

- Accurate focus adjustment

- Customizable power/speed settings

- Enclosed housing or fume filtration

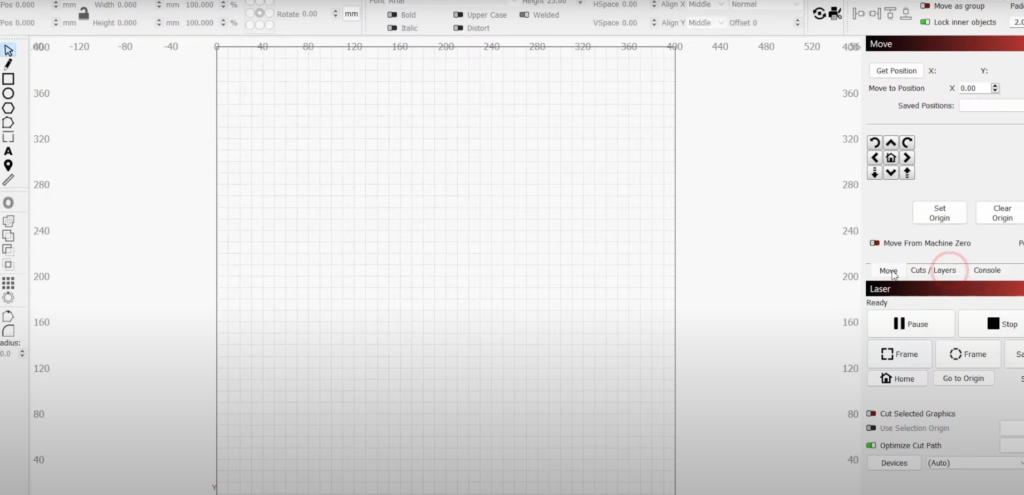

- User-friendly software compatibility (예를 들어, 라이트번)

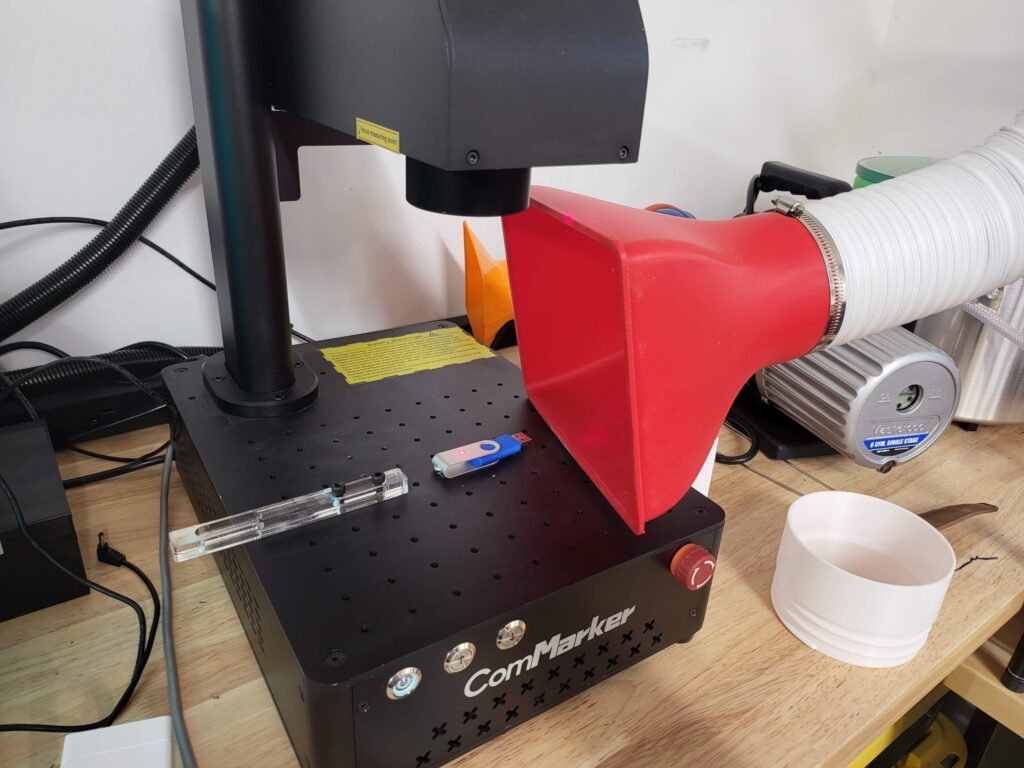

컴마커 Omni 1 UV checks all these boxes and more—making it a top-tier choice for users who want quality without complexity.

Mistake #1: Using the Wrong Material for UV Engraving

자외선 레이저 조각사 are fantastic on plastics, 유리, 가죽, and coated metals—but not all materials are safe or effective.

Common Material Mistakes:

- PVC or vinyl – releases toxic fumes

- Bare metals – may not mark properly without coating

- Cheap acrylic – can melt or discolor under UV

Recommended Materials:

- ABS, PET, and other engineering plastics

- 아크릴 (cast, 희게 센, or coated)

- Glassware (use transfer tape to reduce chipping)

- Painted or coated metals

Always consult your material’s MSDS (Material Safety Data Sheet) and perform a test run before full production.

Mistake #2: Incorrect Power and Speed Settings

Too much power or too little speed can ruin a project. 반면에, conservative settings can lead to faint or unreadable markings.

Fix It With Sample Runs:

- Start with low power and high speed

- Gradually increase until you find optimal clarity

- 사용 LightBurn’s test grid feature to preview results

- Save successful settings as presets in your software

Every UV 레이저 조각사 responds slightly differently depending on the brand, 전원 출력, and lens focal length—so keep records!

Mistake #3: Skipping Focus and Calibration Steps

One of the most overlooked—but critical—steps in UV engraving is focusing your laser. Misaligned focus = blurred, uneven, or incomplete designs.

Solutions:

- Use your engraver’s focus ruler or auto-focus if available

- Perform a dot test to confirm focal height

- Level your engraving surface before running

ㅏ 레이저 조각사 that’s out of focus will also overheat or burn materials unintentionally.

Mistake #4: Ignoring Ventilation and Fume Extraction

Even “cool” lasers like UV models produce fine particulates, especially when engraving plastics or leather. Inhaling these fumes over time is a serious health hazard.

Problems:

- Indoor air quality issues

- Residue buildup on your lens and mirror

- Risk of fire if fumes accumulate

Fix:

- Use an external fume extractor or inline fan

- Keep a clean workspace and vacuum regularly

- Install a carbon or HEPA filter system for added safety

Mistake #5: Not Testing or Previewing the Design

Jumping into a full production run without previewing the layout is a beginner mistake that leads to:

- Misaligned graphics

- Cropped text

- Wasted materials

Use These Tools:

- Frame preview in LightBurn to outline your design

- Dummy material to test placement

- Set your engraver to “low-power dry-run” mode for test tracing

The time you spend previewing can save you hours—and hundreds of dollars—in wasted stock.

Bonus Tip: Maintain Your Laser Engraver Regularly

Your UV 레이저 조각사 is a precision machine. Treat it like one.

유지보수 체크리스트:

- Clean the lens weekly with isopropyl alcohol

- Check air assist (해당되는 경우) for blockages

- Tighten belts or screws quarterly

- Keep software and firmware updated

These quick habits will improve engraving quality and extend the lifespan of your machine.

Best Practices for Beginners Using a UV Laser Engraver

- Wear gloves and goggles during setup and cleaning

- Use design templates to speed up repetitive projects

- Document your settings and results for future reference

- Keep test materials nearby to try new ideas safely

- 작은 것으로 시작하십시오, high-margin products like glassware or jewelry tags

A UV 레이저 조각사 is capable of premium results—but only if you treat it like a pro tool.

컴마커 옴니 1 레이저 조각사

모든 재료를 잠금해제하는 차세대 레이저. ZeroBurn™ 조각 기술 세계 최초의 16K HD 레이저 조각기 10,000mm/s SpeedMax™ 조각 시스템 UV 레이저로 모든 재료 잠금 해제 ColdFront™ 열 기술 전기 리프팅 2 EZCAD 및 LightBurn 360°회전 조각 시스템과 호환되는 옵션 렌즈

Recommended Machine: Why the ComMarker Omni 1 UV Excels

If you’re serious about precision and performance, 그만큼 ComMarker Omni 1 UV laser engraver 제공합니다:

| 특징 | Benefit |

|---|---|

| Low Heat Marking | Prevents material damage on plastics, 유리, 가죽 |

| High Accuracy (0.01 mm) | Perfect for intricate logos or serial numbers |

| Desktop Form Factor | Compact enough for home offices or studios |

| Compatible with LightBurn | Advanced control, image import, batch layouts |

🔗 Learn more about the Omni 1 UV here

FAQs About UV Laser Engraving and Laser Engravers

1분기: Can a UV laser engraver cut materials too?

UV lasers are primarily used for marking and light engraving—not cutting. For cutting, consider a CO₂ or fiber model.

2분기: What’s the difference between UV and fiber lasers?

UV lasers use shorter wavelengths for delicate detail; fiber lasers are better for metal cutting and marking.

3분기: Is a UV laser safe to use at home?

예, but you need proper ventilation and protective gear.

4분기: How long do UV laser diodes last?

Most quality machines offer 20,000 에게 30,000 hours of use.

Q5: Can I engrave colored plastics?

예, UV lasers perform very well on most light and dark plastics.

Q6: Is UV better than CO₂ for clear acrylic?

Yes—UV lasers engrave cleanly on clear acrylic without needing paint or masking.

Work Smarter with Your UV Laser Engraver

A UV 레이저 조각사 is a powerful tool—but even small mistakes can affect your results. By avoiding these five common pitfalls, you’ll enjoy cleaner engravings, fewer errors, and more satisfied clients or customers.

Stay safe, stay focused, 그리고 let your UV laser do the precision work.