파이버 레이저 조각기 have quickly become the go-to solution for businesses, 워크샵, and creators looking for precision, 속도, and durability in metal engraving. If you’ve ever wondered how fiber laser engraving machines manage to cut, 표시, or etch metal with such crisp accuracy, this guide is for you. Whether you’re new to laser technology or considering investing in a machine, understanding how fiber laser engravers work can help you make smarter choices for your business or hobby.

이 기사에서는, we’ll break down the mechanics, 구성 요소, and advantages of fiber laser engravers—plus offer tips on selecting the right model for your workflow.

What Is a Fiber Laser Engraver?

ㅏ 섬유 레이저 조각사 is a type of laser machine that uses fiber-optic technology to generate a concentrated beam of light. Unlike CO₂ or diode lasers, fiber lasers are especially suited for marking metals such as stainless steel, 알류미늄, 놋쇠, 구리, and even gold. They can also engrave some hard plastics and ceramics with the right settings.

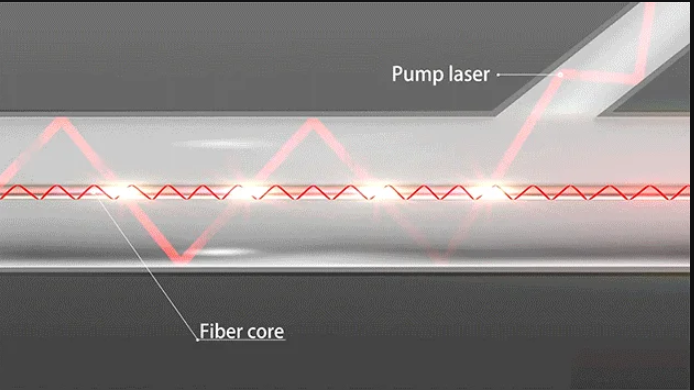

At the core of these machines is a fiber laser source—commonly using a Ytterbium-doped fiber—which channels light through flexible optical fibers, producing a beam with extremely high intensity and precision.

섬유 레이저 조각가 작동하는 방법

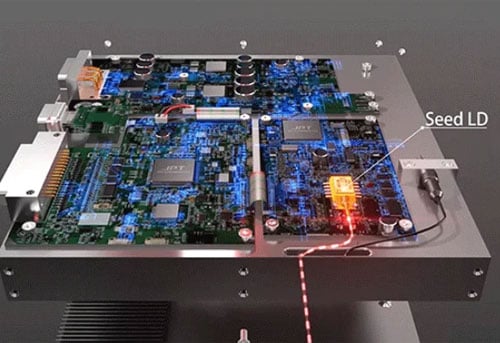

1. Laser Generation

The process starts inside the laser source, where laser diodes emit light into fiber-optic cables doped with rare-earth elements like ytterbium. This “pumping” process excites atoms inside the fiber core, amplifying light into a single coherent beam.

2. Beam Delivery and Focus

This laser beam travels through additional fiber-optic cables into a collimating system and is then focused into a pinpoint using an F-theta lens. The spot size can be as small as 0.01 mm, allowing for incredibly detailed engraving on even tiny objects like jewelry or electronic parts.

3. Galvanometer Movement

Two fast-moving mirrors, called galvanometers, reflect the laser beam onto the work surface. These mirrors adjust the beam’s angle with high precision, allowing the laser to “draw” patterns at speeds up to 15,000 밀리미터/초.

4. 재료 상호작용

When the focused beam hits the material—typically metal—it heats the surface rapidly, vaporizing or oxidizing the top layer. Depending on the power, 빈도, and speed settings, the laser can engrave shallow markings, deep etches, or color effects on stainless steel and aluminum (when using a MOPA fiber laser).

Why Fiber Laser Engravers Are So Effective

Fiber laser engravers are loved for their efficiency and versatility. Here’s why they stand out:

- 높은 정밀도: Spot sizes around 0.01 mm make these engravers ideal for detailed designs and small text.

- 속도: 까지 15,000 mm/s marking speed means high-volume production is no problem.

- 재료 호환성: Works on metals, some plastics, and coated materials.

- Low maintenance: The sealed fiber laser design requires minimal upkeep.

- Long lifespan: Most fiber laser modules are rated for 100,000+ hours of use.

Applications of Fiber Laser Engravers

Fiber laser engravers are used across many industries:

- 보석류: Personalizing rings, 팔찌, and pendants

- 조작: 일련번호, QR 코드, and part traceability

- Gunsmithing: Custom logos and ID markings on firearms

- Tool making: Engraving carbide bits, steel components

- 전자제품: Marking circuit boards, connectors, or casings

Whether you’re making gifts or managing an assembly line, a fiber laser engraver provides the precision and repeatability you need.

What Settings Control the Output?

To get the best results from 섬유 레이저 조각기, you’ll need to master a few key parameters:

| 환경 | What It Does | Recommended Range |

|---|---|---|

| 힘 (%) | Controls energy output | 20%–100% |

| 속도 (밀리미터/초) | Movement of beam | 300–15,000 mm/s |

| 빈도 (kHz) | Pulses per second | 20–100 kHz |

| 펄스 폭 (ns) | 맥박 지속 시간 | 4–400 ns (for MOPA) |

| 라인 간격 (mm) | Distance between hatch lines | 0.01–0.05 mm |

Fine-tuning these settings can mean the difference between a light surface mark and a deep, permanent engraving.

컴마커 타이탄 1 JPT Mopa 파이버 레이저 조각사

그 어느 때보다 강해졌습니다. Designed for Heavy Duty Up to 200W Superpower Electric Lifting with 2 Optional Lenses Color Marking Ability Super 3D Engraving & Cutting Ability 15,000mm/s SpeedMax™ Engraving 8K HD Accuracy Compatible with EZCAD and LightBurn

Recommended Machines: Built for Performance

Looking to get started with 섬유 레이저 조각기 or level up your existing setup? Here are two standout options from 컴마커:

🔧 컴마커 B6 – Compact Powerhouse

- 힘: 20승 / 30승 / 50W fiber

- Perfect for workshops, mobile setups

- 깊은 금속 조각, 명판, 도구

🔥 컴마커 타이탄 1 – Industrial Muscle

- 힘: Up to 200W JPT MOPA

- Great for stainless steel, 검은 색 표시, 컬러 조각

- Ideal for production runs, 3D deep engraving, 그리고 더

Both machines support LightBurn and EZCAD2 software, giving you full creative control and compatibility with popular design tools.

Troubleshooting Tips for New Users

- Engraving too light? Increase power or decrease speed.

- Edges too rough? Adjust line spacing and hatch angles.

- Material not reacting? Make sure it’s compatible with fiber (예를 들어, not glass or acrylic).

- Double images? Check galvanometer calibration or stability of your surface.

Is a Fiber Laser Engraver Right for You?

If your work involves metals or hard plastics—and you need clean, permanent marks—섬유 레이저 조각기 are the best tool for the job. They’re fast, 믿을 수 있는, and capable of producing professional-quality results at scale.

From precision engraving on gun parts to branding metal tumblers or producing serialized parts for industry, the technology behind fiber laser engravers offers both power and control.

👉 Ready to get started? 체크 아웃 ComMarker’s lineup of fiber laser engravers and see which model best fits your needs.