Thinking of buying a laser engraver but not sure which type fits your needs best? 당신은 혼자가 아닙니다. Many makers, 애호가들, and small business owners face this question when deciding between a UV laser engraver and a fiber laser engraver.

In this hands-on comparison, I tested both types of laser engravers on a wide range of materials—metal, 플라스틱, 유리, 결석, 목재, textiles—and logged the real-world differences. If you want to understand what a UV laser can do that a fiber laser can’t (그리고 그 반대), keep reading.

What’s the Real Difference Between a UV and a Fiber Laser Engraver?

Both UV and fiber laser engravers use high-speed galvo systems to create precise marks. But the laser wavelength is where things get interesting:

- 파이버 레이저 operate in the infrared spectrum, relying on heat. They’re ideal for deep metal engravings and rust removal but can damage sensitive materials.

- UV 레이저 조각기 사용 ultraviolet light that reacts photochemically—so instead of burning, they mark by breaking molecular bonds. This allows them to engrave delicate materials like glass, 플라스틱, or textiles without cracking, warping, 아니면 불타거나.

If your projects include a variety of materials beyond just metal, this difference matters a lot.

Laser Engraver Showdown: Head-to-Head Testing by Material

Engraving Metal Business Cards

파이버 레이저: 깊은, high-contrast, 빠른. Great for production.

UV 레이저: Crisp but shallow engraving, not suited for cutting.

Verdict: Fiber laser engraver wins for metal card production.

Raw Metals – Aluminum, 놋쇠, 구리, 스테인레스 스틸

파이버 레이저: Excels across all types—deep engraving, 3D effects, even color (if you’re using a MOPA fiber laser).

UV 레이저: Can engrave, but marks are shallower and fewer visual effects.

Verdict: For industrial-level durability or color effects, fiber is unmatched.

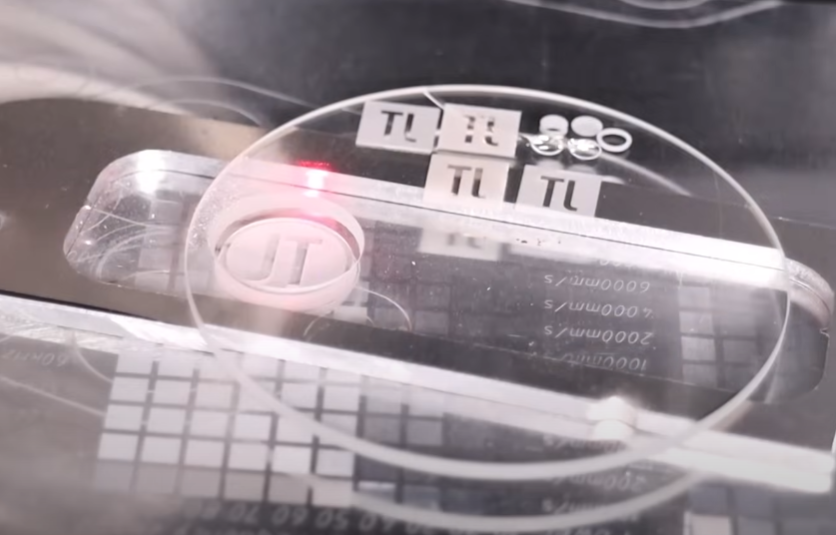

플라스틱 및 아크릴

UV 레이저: This is where it shines. Whether it’s black, 분명한, 색깔의, or even transparent acrylic—UV delivers precise, 깨끗한, high-contrast results without melting.

파이버 레이저: Works well on some plastics but tends to burn or melt the surface. Not reliable across all materials.

Verdict: Laser engraver for plastic? UV is the clear winner.

Glass Engraving and Cutting

UV 레이저: Engraves cleanly with a frosted effect, no cracking. Can even do subsurface engraving and cut thin glass—perfect for custom glassware or awards.

파이버 레이저: Simply can’t engrave glass without a workaround (예를 들어. marking spray or tape), and results are usually poor.

Verdict: If you want to do 유리 조각, a UV laser engraver is the only real choice.

Engraving Wood

UV 레이저: Precise and clean engravings with no smoke stains. Ideal for fine detail work like signs or jewelry boxes.

파이버 레이저: Struggles. Most fiber engravers won’t even leave a mark on wood.

Verdict: Use a UV laser engraver for wood, especially if contrast isn’t your top priority.

Engraving Textiles & 가죽

UV 레이저: Ablates the surface dye, leaving soft fabrics intact. Works great on denim, 폴리 에스테르, and even microfiber towels.

파이버 레이저: May not mark at all, or might melt/burn the fabric.

Verdict: UV is best for engraving textiles and gives better results on leather too—no burn marks.

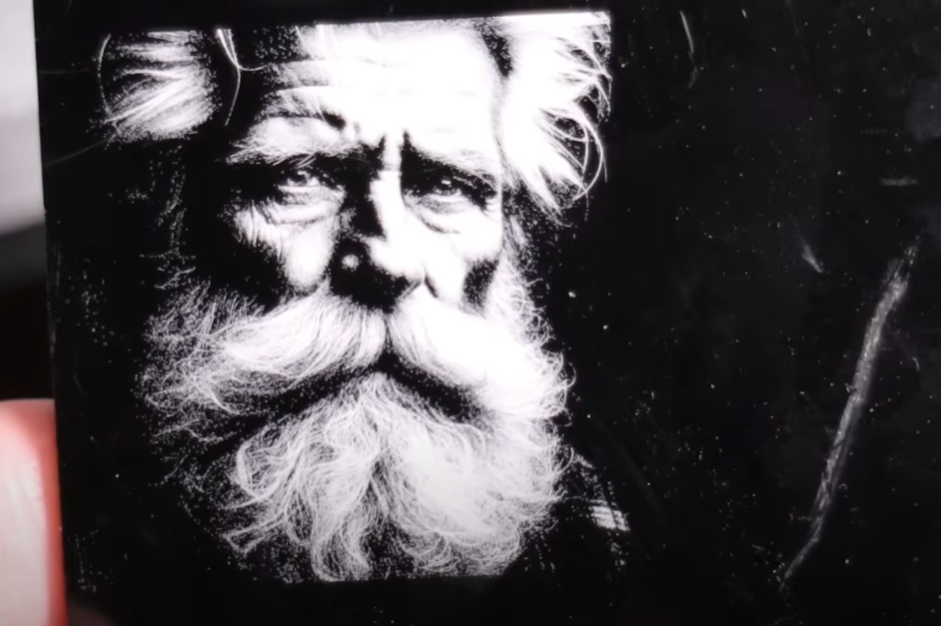

Engraving Stone

파이버 레이저: Can go deep and fast—good for awards, stone coasters, 등.

UV 레이저: Can engrave some types, but marks are shallower and less consistent.

Verdict: Fiber laser is better for engraving on stone unless extreme detail is required.

Specialty Use Cases

- Rust Removal: Fiber laser wins hands down.

- PCB Prototyping: Fiber laser’s precision and power make it ideal for etching and drilling copper.

- Rubber Stamp Making: UV laser offers cleaner results with crisp detail.

- Engraving Ceramic Cups: UV laser removes paint cleanly with no charring.

- Engraving Cardboard or Leaves: UV laser handles these fragile materials effortlessly.

Which Laser Engraver Should You Choose?

Still wondering what the best laser engraver is for your DIY workshop or small business? Here’s a quick summary based on use case:

컴마커 옴니 1 레이저 조각사

모든 재료를 잠금해제하는 차세대 레이저. ZeroBurn™ 조각 기술 세계 최초의 16K HD 레이저 조각기 10,000mm/s SpeedMax™ 조각 시스템 UV 레이저로 모든 재료 잠금 해제 ColdFront™ 열 기술 전기 리프팅 2 EZCAD 및 LightBurn 360°회전 조각 시스템과 호환되는 옵션 렌즈

Choose a UV 레이저 조각사 if you:

- Want to engrave plastic, 아크릴, 아니면 유리

- Work with delicate or colored materials

- Need precision and detail without heat damage

- Want to engrave fabric, 가죽, or wood with clean lines

- Are making custom gifts, 공예, or art pieces

ComMarker B6 파이버 레이저 조각기

어디서나 정확하면서도 스마트한 레이저. 레코드 브레이크 컴팩트 크기 2-in-1 디자인 자동 초점 기술 15,000mm/s speedmax ™ 조각 8K HD 정확도 스마트 LED 터치 스크린 콜드 프론트 ™ 열기 기술 클래스 1 안전 레이저 기계

Choose a 파이버 레이저 조각사 if you:

- Focus mainly on metals (특히 스테인리스, 놋쇠, or copper)

- Need deep, durable engravings

- Want color marking on stainless steel (MOPA only)

- Need to remove rust or etch PCBs

- Value speed and power for high-volume production

Choosing the Right Laser Engraver for Your Projects

There is no universal “best” laser engraver—it comes down to your materials, projects, and business goals.

나를 위한, running both a UV and fiber laser engraver side-by-side lets me cover everything from custom tumblers and cutting boards to serial-coded metal parts and glass ornaments.

If you’re just starting out and want a versatile tool for 플라스틱, 유리, and detailed engraving, go with a UV 레이저 조각사.

If your projects demand metal engraving at production scale, ㅏ 섬유 레이저 조각사 is your best bet.