Getting the perfect focus on your 레이저 조각사 is the secret to clean cuts, 좋은 세부 사항, and consistent results. But here’s the hard truth: those acrylic spacers or preset focus gauges your manufacturer included? They’re probably wrong. 사실은, DIY expert Rich from Louisiana (a.k.a. The Louisiana Hobby Guy) discovered his official 18mm spacer was off by 2 full millimeters.

So how do you dial in your laser engraver the 오른쪽 way? It’s called the Focus Ramp Test, and it takes less than 15 minutes to run in LightBurn.

그것을 분해하자, 단계별로.

🔧 Step-by-Step: How to Run a LightBurn Ramp Test for Laser Focus

단계 1: Set Up the Line in LightBurn

- 사용 Pencil Tool to draw a straight line about 10 신장 (240mm) 긴.

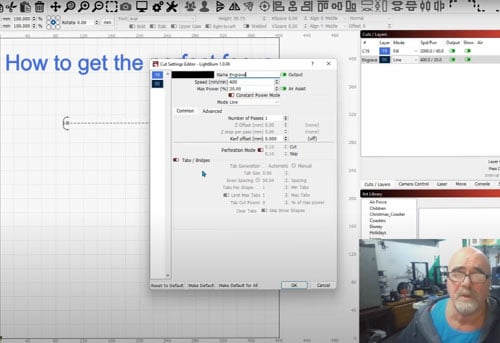

- Set the line to ENGRAVE mode, 사용 low power (15–20%), 그리고 느린 속도 (400–620 mm/s).

- Turn OFF air assist to avoid beam interference.

- ✅ 팁: Right-click the layer name and click “Make Default” to save these settings for future tests.

단계 2: Prep the Material

- Grab a piece of scrap wood or acrylic.

- Shim one side of the material up by 10–12mm to create a sloped ramp.

- Tape the material securely to your bed—movement will ruin the test.

단계 3: Position the Laser

- In LightBurn, switch to “Absolute Coordinates”.

- Move your laser head to the low end of the sloped material (where the burn will start).

- Make sure the beam will travel along the incline, not across it.

단계 4: Run the Engraving

- Start the job. The laser engraver will draw a thin line along the sloped surface.

- When complete, look for the thinnest, sharpest point of the line—that’s your sweet spot.

- Mark that point with a pencil or fine marker.

단계 5: Measure the Real Focus Height

- Use digital calipers to measure from the laser’s frame or bed to the marked spot.

- Repeat 2–3 times for accuracy.

- In Rich’s example, the correct height came out to around 16mm, not the 18mm spacer the manufacturer included.

🎯 Why This Test Beats Manufacturer Focus Tools

1. Factory Focus Spacers Are Often Inaccurate

Most acrylic blocks are mass-produced, and a 1–2mm error is not uncommon. That’s enough to throw off your engraving detail or require extra cutting passes.

2. The Ramp Test Works with Any Laser Engraver

다이오드, co₂, fiber—just adjust your power and speed accordingly:

- CO₂ 레이저 조각사: Use slightly higher power (~10–15%) and faster speed to prevent burning.

- 다이오드 레이저: Use 15–20% power, 느린 속도.

- 파이버 레이저: Stick to low marking settings and short line distances.

3. No Fancy Tools Needed

Just:

- Scrap material

- Calipers

- Tape

- LightBurn 소프트웨어

- Your laser engraver

🔍 Pro Tips from Rich (Louisiana Hobby Guy)

- Name your layers in LightBurn. Save engraving and cutting profiles with default labels like “Wood Cut” or “Metal Mark.”

- Quick flip shortcut: Tap the comma

,or period.to flip your design horizontally or vertically. - Invest in Calipers: A good set of digital calipers costs less than $25 and lasts forever.

- Check Often: Repeat the ramp test every time you change materials, swap lenses, or move your laser.

📊 What Happens When Focus Is Dialed In Perfectly?

- Sharper detail (예를 들어, firefighter logos, name badges, small text)

- Cleaner cuts with fewer passes and less char

- Consistent depth—especially important for engraving on curved surfaces

- More efficiency—saves time, saves money

Whether you’re engraving leather luggage tags, customizing dog tags, or batch cutting keychains, precision focus equals better profit.