If you’re thinking about laser printing on metal, the first question you’ll probably ask is: Can a laser engraver really handle that? The short answer—absolutely yes. Whether you’re working with stainless steel, aluminium, messing, or titanium, a good lasergraver can mark, etch, or even deeply engrave metal with precision. I denne veiledningen, we’ll break down what kind of laser you need, which metals work best, what specs actually matter, and how to choose a laser engraver that gives you professional results—without breaking the bank.

Why Laser Engraving Dominates Metal Marking

Laser engraving is the #1 method for permanent metal marking on stainless steel, aluminium, messing, og titan. Unlike mechanical engraving, it offers:

✅ Micro-Precision: 0.001mm spot size (f.eks., ComMarker Omni 1) for intricate serial numbers, logoer, or artwork.

✅ Zero Contact: No tool wear, burrs, or material distortion.

✅ Industrial Durability: Resists chemicals, varme, and abrasion.

✅ Hastighet: Engrave a custom knife in 60 seconds or 100 ID tags/hour.

4 Critical Factors When Choosing a Metal Laser Engraver

1. Laser type

| Type | Best for | Avoid If You Need… |

|---|---|---|

| Fiber | Raw metals (stål, Ti) | Under $2K budget |

| MOPA | Fargemerking på rustfritt | Basic etching only |

| UV | Coated metals, smykker | Dyp gravering (>0.2mm) |

2. Power Requirements

- 20W–50W: Marking/text (f.eks., serienummer)

- 60W–100W+: Dyp gravering (0.1–0.5mm) or cutting

- <5W UV: Surface marks on plated/coated metals

3. Arbeidsområde Størrelse

- 110× 110mm: Smykker, small tools

- 300×300mm+: Skytevåpen, industrial plates

4. Pulse Control (MOPA Tech)

Essential forcolor marking stainless steel (black/gold/blue) by adjusting frequency and pulse width.

(Keywords: “fiber vs UV laser,” “MOPA metal marking,” “laser wattage guide”)

ComMarker Titan 1 JPT Mopa Fiber Laser Engraver

Sterkere enn noen gang. Designed for Heavy Duty Up to 200W Superpower Electric Lifting with 2 Optional Lenses Color Marking Ability Super 3D Engraving & Cutting Ability 15,000mm/s SpeedMax™ Engraving 8K HD Accuracy Compatible with EZCAD and LightBurn

Topp 3 Laser Engravers for Metal (2025 Tests)

- ComMarker B6 MOPA (20W–50W)

- Best for: Small shops, color marking knives/tools

- Key Specs: 0.01mm spot, 110×110mm area, bærbar

- ComMarker Titan 1 (60W - 200w)

- Best for: Deep engraving firearms/machinery parts

- Key Specs: 3D gravering, 6000mm/s speed, 300×300mm area

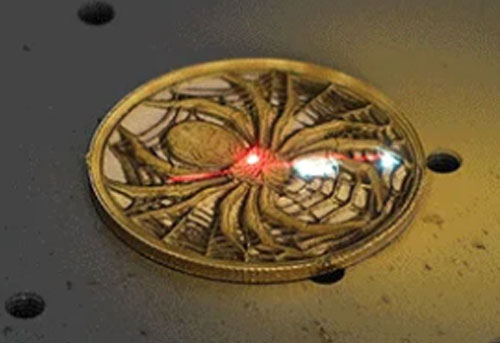

- ComMarker Omni 1 UV (5W)

- Best for: Smykker, elektronikk, belagte metaller

- Key Specs: 0.0019mm spot, non-thermal process

Proven Laser Settings for Common Metals

Tested parameters forcrisp, consistent results:

| Metall | Makt | Hastighet | Frekv. | Air Assist? |

|---|---|---|---|---|

| Rustfritt stål | 80–100% | 300–500 | 30–60 | Ja |

| Aluminium | 20–50% | 600–1000 | 20–30 | Valgfri |

| Messing | 60–90% | 200–400 | 40–60 | Ja |

| Titanium | 70–100% | 400–700 | 50–80 | Ja |

⚠️Critical: Always run afocus test (ramp method) before production. Material thickness affects beam convergence.

(Keywords: “laser settings for stainless steel,” “metal engraving parameters”)

5 High-Profit Metal Engraving Applications

- Custom Knives/Tools: Logoer, ownership marks (50–100W fiber)

- Tumlere & Drinkware: Full-wrap designs (MOPA for color)

- Smykker: Micro-engraving pendants/rings (UV laser)

- Skytevåpen: Compliance markings + personalisering (check ATF rules!)

- Aerospace ID Plates: Barcodes, serier (fiberlaser)

4 Costly Mistakes to Avoid

- Using CO₂ on bare metal → Leaves faint/unreadable marks.

- Skipping fume extraction → Metal vapor is toxic (install exhaust + filter).

- Engraving coated metals too deep → Peeling/cracking (bruk <0.05mm depth).

- Guessing focus → Calibrate with a ramp test for sharpness.

The Verdict

Ja, laser engravers excel with metal – butfiber/MOPA lasers are essential for professional results. For under $5K, models like theComMarker B6 deliver precision rivaling industrial machines.

🔥Hot Tip: Need deep engraving? Prioritizepulse energy over wattage. A 50W MOPA often outperforms 100W non-MOPA lasers.

Ready to Start?

→ Compare Metal Laser Engravers

FAQ Section (Schema-Rich)

Q: Can diode lasers engrave metal?

EN: Only with thermal spray coatings (f.eks., Cermark). Fiber/UV lasers are required for raw metal.

Q: How deep can a 50W laser engrave metal?

EN: 0.1–0.3mm on steel/brass (after 3–5 passes).

Q: Why does stainless steel turn black when engraved?

EN: MOPA lasers oxidize the surface – adjust pulse width for gold/blue effects.