Velge riktig laser source is one of the most critical decisions when buying a lasergraver. Whether you’re customizing wood gifts, marking metal tools, or personalizing glassware, your engraver’s performance—and limits—are defined by the type of laser it uses. I denne artikkelen, we’ll break down the core types of laser sources (Co₂, fiber, og UV), explore their differences in wavelength and power, and help you decide which one suits your real-world needs.

What Is a Laser Source? (CO₂ vs Fiber vs UV)

A laser source in a lasergraver is the component that emits the high-energy beam used to mark or cut materials. Different source types use different physics—and that greatly affects what materials they can engrave.

| Type | Bølgelengde | Best for | Common Use Cases |

|---|---|---|---|

| Co₂ | 10,600 nm | Organic materials like wood, lær, akryl | Crafting, skilting, emballasje |

| Fiber | 1064 nm | Metaller, hard plast | Metallmerker, verktøy, Industrielle deler |

| UV | 355 nm | Heat-sensitive materials like plastic, glass, keramikk | Precision marking, elektronikk, medisinsk utstyr |

✅ Tupp: The shorter the wavelength, the better it handles fine, heat-sensitive, or brittle materials.

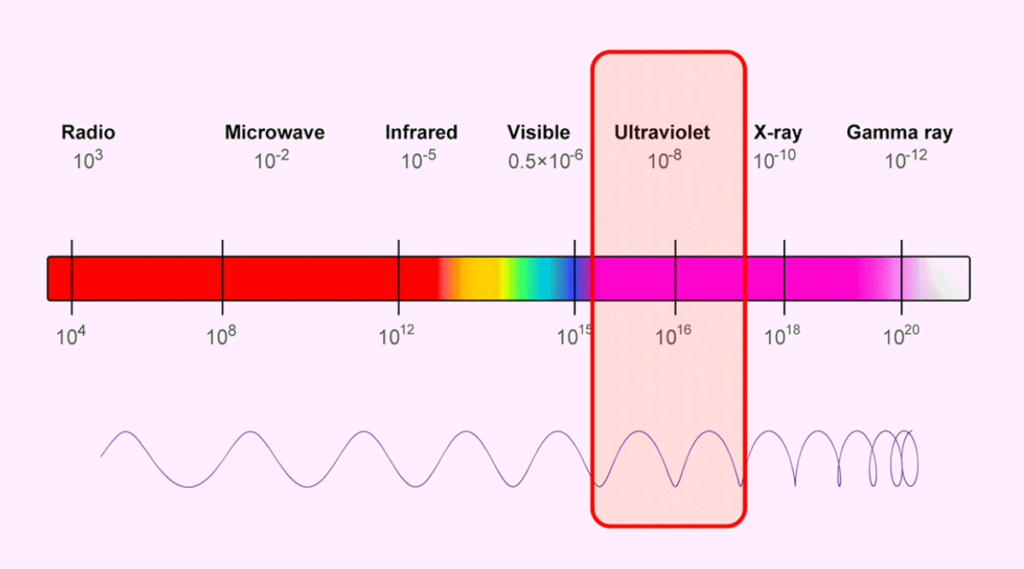

Why Wavelength Matters: Matching to Materials

De wavelength of the laser determines how deeply and cleanly it interacts with specific materials.

- CO₂ lasers (10,600 nm) are absorbed well by non-metals, making them ideal for engraving wood, akryl, papir, og skinn.

- Fiberlasere (1064 nm) penetrate metals effectively due to higher photon energy at that wavelength.

- UV-lasere (355 nm), like those used in the ComMarker Omni 1, are absorbed on the surface without heat buildup, making them perfect for plastics, glass, og keramikk.

Power vs Efficiency: Does Higher Wattage Mean Better Engraving?

Not always.

- Higher wattage means faster marking or deeper engraving—but only when paired with the right wavelength and lens system.

- A 5W UV laser can outperform a 20W fiber laser on plastic or glass, because the UV wavelength interacts better with those materials.

Here’s an example from real tests using the ComMarker Omni 1 UV lasergraver:

| Materiale | Laserkilde | Power Used | Resultat |

|---|---|---|---|

| White ABS Plastic | UV (355nm) | 5W | High-contrast black mark, no melting |

| Rustfritt stål | UV (355nm) | 5W | Light surface mark only |

| Tre | Co₂ (10,600nm) | 40W | Deep and wide engraving |

Choosing the Right Laser Source: What to Consider

When deciding which lasergraver to buy, focus on:

- Material types you work with most

- Engraving depth vs. hastighet (Do you need surface marks or deep cuts?)

- Level of detail (QR -koder, tiny text, fine lines? UV wins here)

- Budsjett (CO₂ lasers are usually more affordable for hobby use)

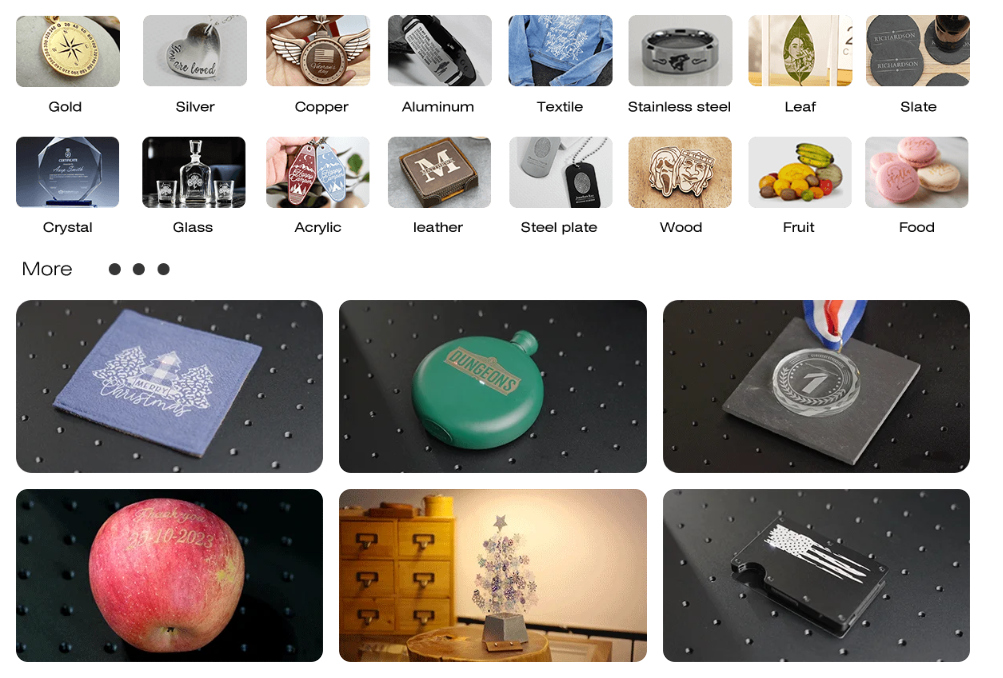

Real-World Use Case Examples

- A jewelry crafter working with gold and silver → Go for a fiberlaser

- A DIY creator customizing tumblers and wood signs → Best with a CO₂ laser

- A startup marking logos on phone cases, briller, and ceramic mugs → Choose a UV laser, liker Omni 1

ComMarker Omni 1 Lasergravør

Neste generasjons laser for å låse opp alle materialer. ZeroBurn™ graveringsteknologi Verdens første 16K HD lasergravør 10 000 mm/s SpeedMax™ graveringssystem Lås opp alt materiale med UV-laser ColdFront™ termisk teknologi elektrisk løft med 2 Valgfrie linser kompatible med EZCAD og LightBurn 360° roterende graveringssystem

Which Laser Source Is Right for You?

The best laser engraver isn’t just about power—it’s about matching the laser source to your application. If you’re engraving a variety of delicate or non-metal materials, de ComMarker Omni 1 UV lasergraver offers professional-level precision with minimal heat impact. For metals or bulk engraving, fiber and CO₂ still have the edge.

Need help choosing? Visit ComMarker.com to explore laser engravers tailored to your material needs.