When you’re investing in your first or next laser machine, deciding between a 5W UV laser engraver and a 20Gravador a laser de fibra W can feel like comparing apples to oranges. Both technologies are incredibly capable—but they shine in very different ways. Whether you’re customizing glassware, marking metals, or launching a small laser business, the choice you make can dramatically impact your workflow, materiais, and results.

Neste guia, we’ll break down the differences between UV and fiber laser engravers, with a special focus on 5W UV vs. 20W fibra systems. We’ll help you match the right tool to your projects—so you don’t overbuy or underperform.

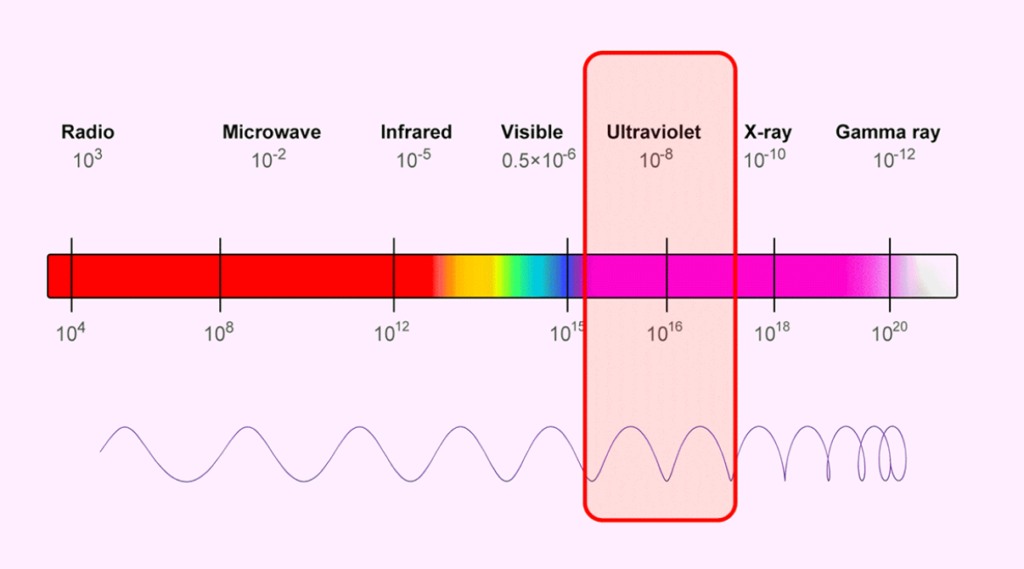

Understanding the Basics: UV vs.. Fibra

Before diving into the wattage, let’s clear up the core technology.

- Gravadores a laser UV (355 nm): These use short-wavelength ultraviolet light that interacts with materials on a photochemical level. Isso significa less heat, which is great for delicate surfaces.

- Gravadores a laser de fibra (1064 nm): These operate using a solid-state laser source, producing powerful beams that engrave by thermal interaction. They’re ideal for metals and other high-density materials.

👉 In short: UV = cool and precise. Fiber = hot and strong.

Why Power Ratings Matter — But Not Everything

A 20W fiber laser engraver is not “four times better” than a 5W UV. Wattage impacts speed and depth, mas o type of laser determines what materials you’re working with and how clean your results are.

Let’s compare:

| Recurso | 5Laser UV W | 20W Fiber Laser Engraver |

|---|---|---|

| Melhor para | Plásticos, vidro, acrílico, couro, PCB | Metais (aço, latão, alumínio), anodized materials |

| Engraving Detail | Extremely fine (spot size ~0.002mm) | Sharp on metal, but larger spot size (~0.01mm) |

| Thermal Damage | Very low – ideal for delicate surfaces | Moderate to high – can discolor or warp soft materials |

| Gravura colorida | Not applicable | Opcional (with MOPA model upgrades) |

| Cutting Capability | Very limited | Can engrave deep or cut thin metals |

| Velocidade | Moderado | Fast for metals |

When to Choose a 5W UV Laser Engraver

You should go UV if:

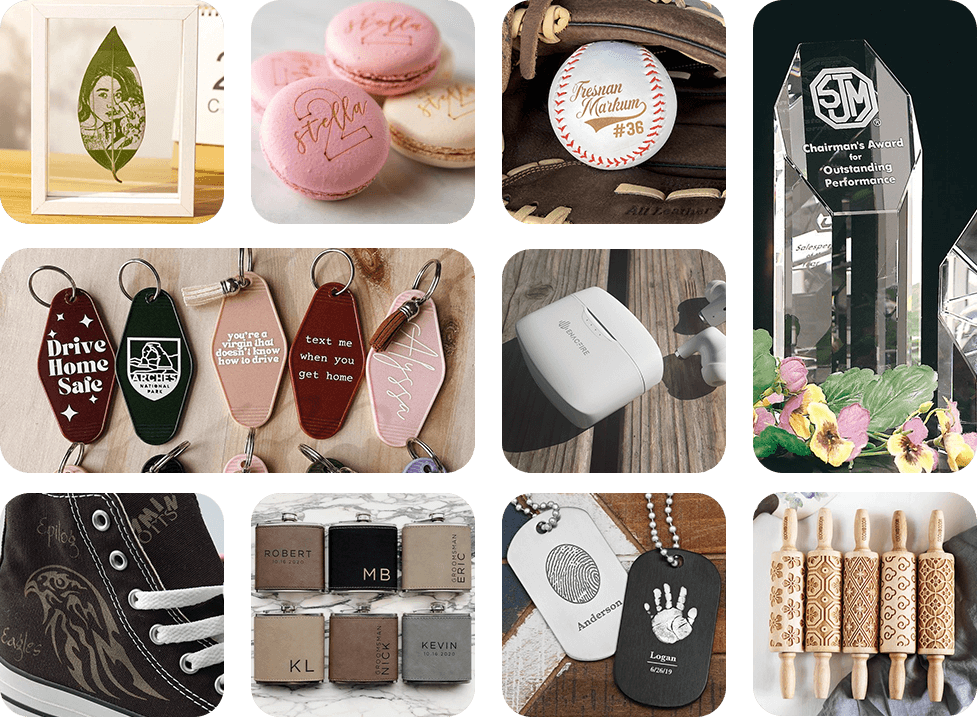

- You engrave vidro, acrílico, or clear plastics (which fiber lasers can’t touch).

- You want pinpoint precision for micro-text, Códigos QR, logotipos, or electronics.

- You run a business making Presentes personalizados, joia, copos, or leather products.

- You care about sem marcas de queimadura and perfect edges on sensitive items.

✅ Recommended: ComMarker Omni 1 Gravador a laser UV

With 16K resolution, ZeroBurn ™ Tech, and compatibility with LightBurn, o Omni 1 is a small-format powerhouse perfect for detailed, multi-material work.

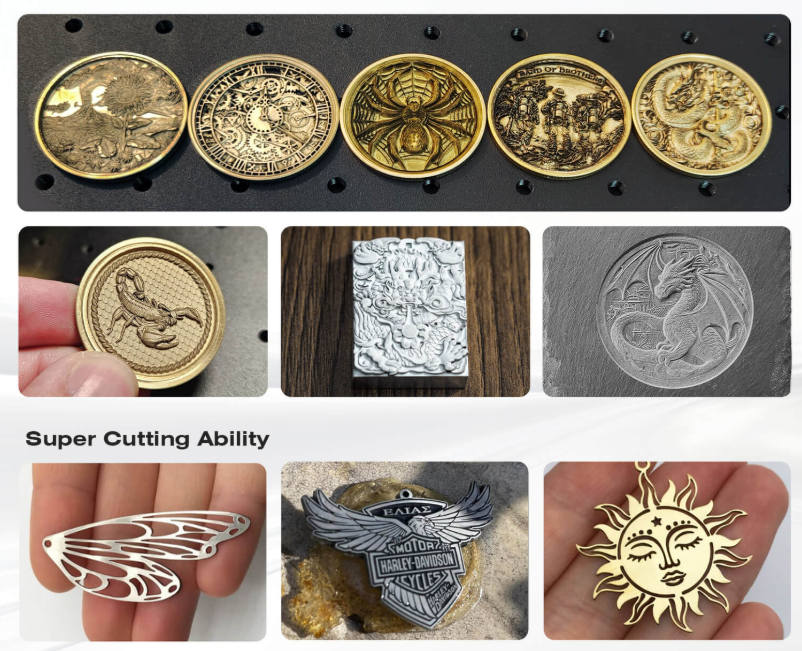

When to Choose a 20W Fiber Laser Engraver

You should go fiber if:

- You engrave metal daily (por exemplo, stainless steel tags, ferramentas, weapons, or serialized parts).

- You need faster production and deeper engraving than a UV laser offers.

- You want a machine that works with alumínio anodizado, latão, cobre, e mais.

- You need a rugged, fast setup for industrial or business use.

✅ Recommended: Gravador a laser de fibra ComMarker B6 (20C)

With 0.01mm precision and ultra-portability, the B6 delivers professional-grade metal engraving in a lightweight, shop-friendly package.

Use Case Scenarios

Here’s what a few typical users might choose:

- Maker doing etched wine glasses and leather coasters? → Omni 1 ultravioleta

- Gunsmith marking steel slides or AR lowers? → B6 Fiber

- Small biz customizing tumblers, Tag, and wood boxes? → Consider Omni 1 for precision or B6 for speed.

- Engraving circuit boards or plastic enclosures? → UV is your best friend.

What About Maintenance and Ease of Use?

- Laser UV: Typically more compact, lighter, and quieter. They need ventilation for materials like acrylic or plastic.

- Lasers de fibra: Built tougher for heavy-duty use. They can be louder, and often need more robust electrical and cooling setups.

💡 Both the Omni 1 e B6 come with intuitive software options like LightBurn e EZCAD, and both support rotary attachments for cylindrical engraving.

Solução de problemas comuns

For UV Laser Engraving:

- If results are faint on glass, double-check focus height and reduce speed.

- Ghosting or foggy lines? Improve airflow and add painter’s tape to glass.

For Fiber Laser Engraving:

- Uneven depth on metal? Recalibrate Z-height and test hatch spacing.

- Discoloration or burn marks? Reduce power or increase frequency.

ComMarker Omni 1 gravador a laser

Laser de última geração para desbloquear todos os materiais. Tecnologia de gravação ZeroBurn™ O primeiro gravador a laser 16K HD do mundo Sistema de gravação SpeedMax™ de 10.000 mm/s Desbloqueie todo o material com laser UV Tecnologia térmica ColdFront™ Elevação elétrica com 2 Lentes opcionais compatíveis com sistema de gravação rotativa EZCAD e LightBurn 360°

Choose Smart, Not Just Strong

Don’t let wattage alone drive your purchase. A 20Gravador a laser de fibra W is a beast with metal—but for mixed materials, clean finishes, or ultra-fine work, a 5Laser UV W may outperform it.

🔥 Want the best of both worlds? Start with the Omni 1 for intricate work, and scale up to the Titã 1 ou B6 for serious metal production.