If you’ve ever worked with plastic parts and needed to add permanent serial numbers, you’ve probably wondered: Can a laser engraver do this accurately? The answer is yes—and in this project, I’ll walk you through how I used the ComMarker Omni 1 UV laser engraver to mark nearly 40 plastic key fobs with crisp, readable codes. This job also gave me a great opportunity to build a quick custom jig, streamline the workflow, and take full advantage of the laser engraver’s precision on plastic.

Why I Chose a UV Laser Engraver for Plastic Projects

Not all laser engravers handle plastic the same way. In my experience, diode or CO₂ laser engravers can melt or discolor certain plastics. That’s why I used the КомМаркер Омни 1, a UV laser engraver that offers a clean “cold burn” ideal for delicate materials.

Лучшее для: Пластик, стекло, акрил, кожа, and coated materials

Settings used:

- Скорость: 1000 мм/с

- Частота: 40 кГц

- Линейный интервал: 0.03 мм

- Q pulse: 15

- Crosshatch fill, 1 проходить

You can check out the Омни 1 UV laser engraver here.

Шаг 1: Trace the Object and Create a Jig for Your Laser Engraver

A reusable jig helps you place parts accurately every time you use your laser engraver. I started by tracing a key fob on white paper with alignment marks, took a top-down photo, and imported it into LightBurn. I scaled it using a 1-inch guide, then used the “Trace Image” tool to create a clean path around the shape.

Для чаевого: Make sure your traced image has clear lines and good contrast for LightBurn to pick up the edges accurately.

Шаг 2: Add Alignment and Finger Access Features to the Jig

I used LightBurn’s “Offset” and “Node Edit” tools to trim the top of the cutout and added a finger hole using a simple circle tool. These small details ensure that the key fobs are easy to remove once the laser engraving is done.

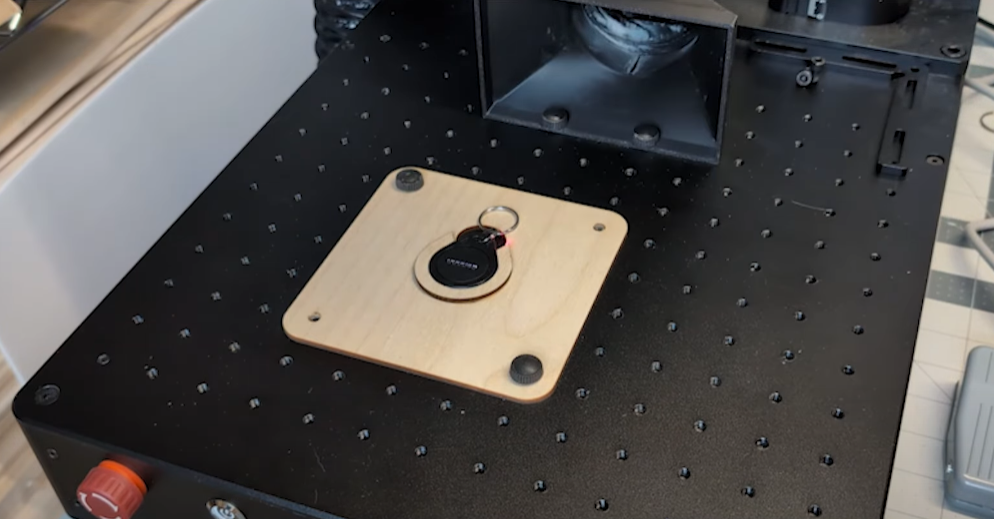

Шаг 3: Mount the Jig and Center It in Your Laser Engraver

Once the jig was cut out on a 3mm Baltic birch using a CO₂ laser, I glued the layers together and mounted it to the Omni 1’s working bed using the 5mm bolts. The jig held each key fob snugly and aligned perfectly with the laser engraver’s target area.

Шаг 4: Add Serial Numbers Using LightBurn’s Variable Text Tool

Using LightBurn’s “Serial Number” feature, I created four-digit codes starting from 0030. This feature allows the laser engraver to automatically advance to the next number after each burn, saving time and minimizing errors.

Settings for numbering:

- Text type: Serial number

- Format: 0000

- Starting value: 0030

- Auto advance: ON

Шаг 5: Burn and Batch Engrave Using the Laser Engraver

Once aligned, each key fob took about 4 seconds to engrave. I simply dropped in the next fob, pressed the button, and let the laser engraver do its thing. The UV laser produced a clean, high-contrast mark on every plastic surface.

Бонусный совет: Keeping Serialized Items in Order

To organize all the engraved key fobs, I printed a DIY cable chain using PLA and TPU and loaded the fobs in reverse order. It’s not permanent, but a handy temporary solution while waiting for a steel cable version.

КомМаркер Омни 1 Лазерный гравер

Лазер нового поколения для открытия всех материалов. Технология гравировки ZeroBurn™ Первый в мире лазерный гравер с разрешением 16K HD Система гравировки SpeedMax™ со скоростью 10 000 мм/с Разблокируйте все материалы с помощью УФ-лазера Термальная технология ColdFront™ Электрический подъем с помощью 2 Дополнительные линзы, совместимые с EZCAD и поворотной гравировальной системой LightBurn на 360°.

Why a UV Laser Engraver Was the Right Tool for the Job

This project reinforced just how useful a лазерный гравер like the ComMarker Omni 1 can be for small production runs, especially on tricky materials like plastic. Точность, скорость, and ease of automation made it a no-brainer. Whether you’re doing serialized key tags, ID cards, or small parts, a UV laser engraver is a great investment.

Recommended machine: КомМаркер Омни 1 УФ лазерный гравер

Лучшее для: Пластик, стекло, акрил, and precision batch jobs

Key takeaway: A good jig and serial-number automation can save you hours.