这 ComMarker Omni 1 is not your average desktop 激光雕刻机. With a pulsed 355 nm UV laser, sub-25 nanosecond pulse widths, and swappable F-Theta lenses, it enters a new class of photonic precision. But what makes it different—and why would anyone choose this over a higher-powered 60W infrared fiber system?

Let’s take a look under the hood, at the beam, and deep into the glass.

UV vs IR: Why Wavelengths Matter

Infrared lasers (like fiber and MOPA) dominate in general purpose engraving: 金属, 颜色标记, deep cutting. But UV lasers, with their shorter wavelength, open doors to materials that are transparent to IR—like plastics, 木头, 玻璃, or PCBs.

UV’s shorter wavelength:

- Enables photochemical ablation rather than thermal burning

- Creates extremely small spot sizes for high DPI and clean micro-cuts

- Allows for sub-surface engraving in transparent materials

结果: Less heat, more control.

Optical Precision – The Truth About Spot Sizes

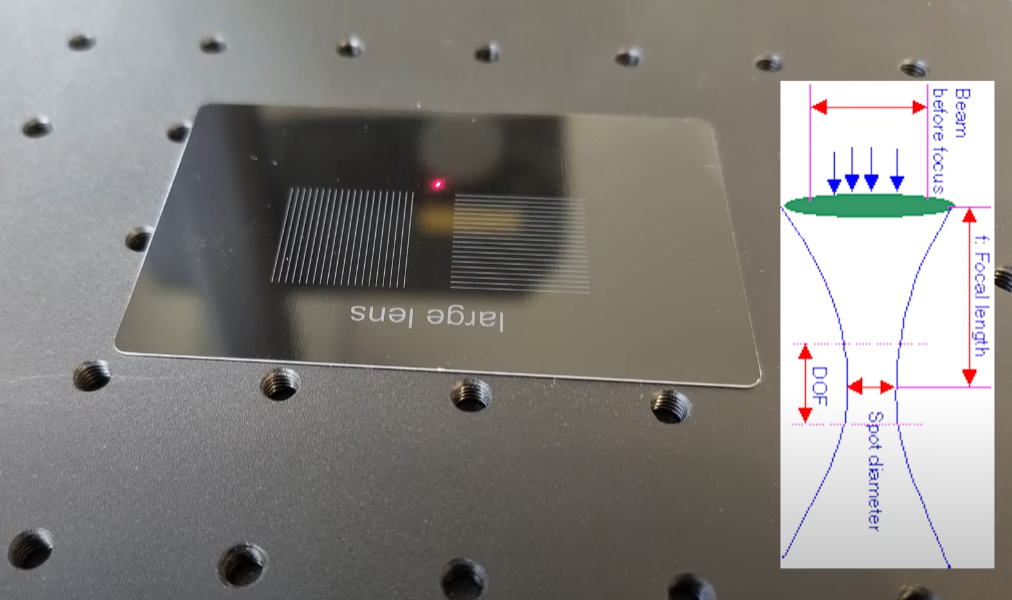

奥姆尼 1 includes two F-Theta lenses:

- 70×70 mm lens – Shorter focal length, smaller spot size

- 150×150 mm lens – Larger working area, but lower resolution

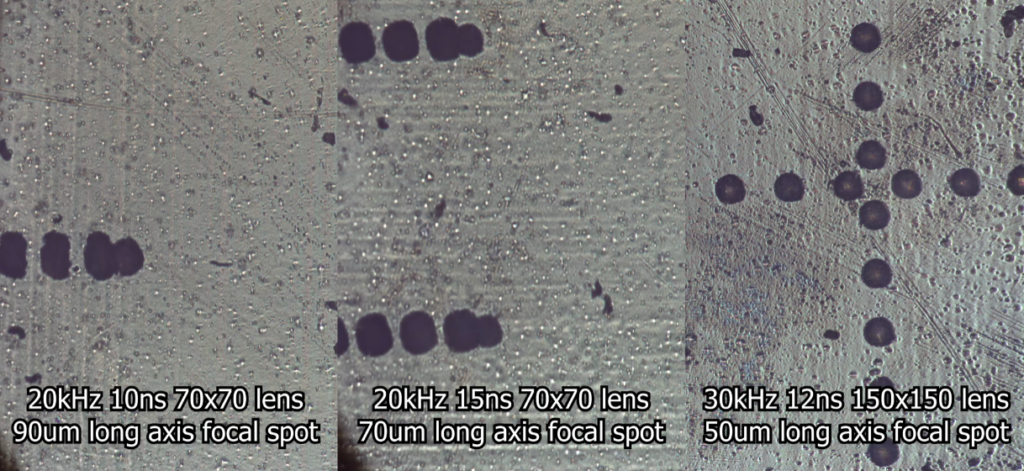

While theory suggests sub-40μm spot sizes, real-world measurements yielded:

- ~53 μm with the large lens

- ~40 μm with the small lens (with fine-tuning)

For comparison: CO₂ lasers typically operate in the 100–200 μm range.

Pulse Widths and Beam Quality – Why It Matters

奥姆尼 1 allows users to dial in 频率 (千赫) 和 脉冲持续时间 (纳秒):

- Best results (roundest beam profile): 30 千赫 / 12 纳秒

- Too short or too long disrupts beam symmetry (TEM00 degrades)

Changing pulse parameters dramatically affects:

- Beam shape

- Focus accuracy

- Energy delivery per impulse

This matters especially for glass work, PCB micromachining, 和 surface coatings.

Application Highlights

Here’s where this UV laser shines:

| 材料 | 结果 |

|---|---|

| 塑料 | Crisp white marks, no melting or charring |

| 木头 | 干净的, micro-thin cuts with minimal burn |

| 玻璃 | Can embed 3D models 里面 the glass |

| 多氯联苯 | Micro-etch traces with <100μm precision |

| 纺织品 | Surface bleaching or engraving without damage |

| 硅 / ICs | Selective removal of epoxy molding |

笔记: Always use proper dust extraction. UV glass cutting releases hazardous micro-particles.

Inside the Omni 1 – A Technical Teardown

Control and Optics:

- JCZ controller card

- True Galvo mirrors

- Motorized Z-axis (on newer models)

- 软件: 光烧 (limited for automation), or open-source Balor

激光模块:

- DPSS laser with Nd:YAG crystal

- Q-switch driver for nanosecond-scale gating

- Tripled frequency via harmonic generation to 355 纳米

- Thermoelectric cooling throughout

- Accessible pump diode (replaceable)

⚠️ Tip: Beam parameters affect thermal lensing in crystals—keep pulse energy consistent.

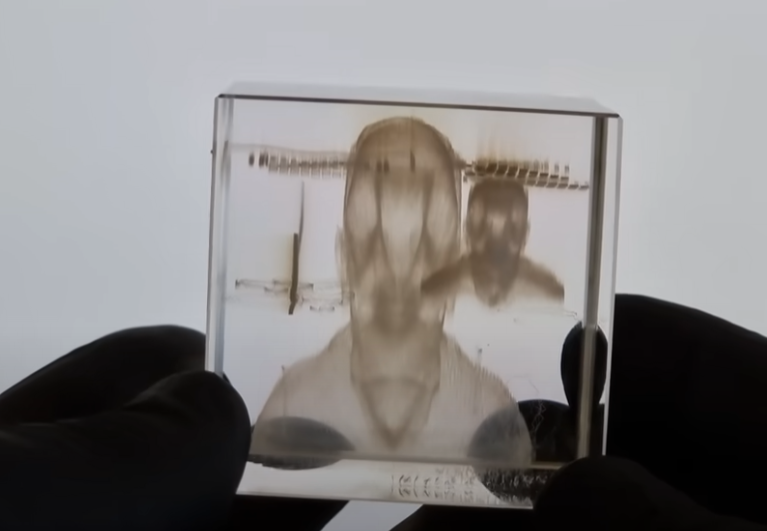

Nerd Feature: 3D Models Embedded in Glass

By compensating Z-height for glass’s refractive index, 奥姆尼 1 可以雕刻 3D voxels at varying depths inside a cube. This opens up:

- Microfluidic devices

- Embedded art

- Secure 3D data markers

- Experimental optics and light-guiding structures

Requires:

- G-code slicing of 3D models

- Python scripting (via Balor CLI)

- Fine-tuned pulse parameters (例如, 38千赫 / 12纳秒)

Final Verdict

优点:

✅ Unmatched versatility across exotic materials

✅ Sharp, minimal heat cuts and marks

✅ Compact yet hackable design

✅ Perfect for PCBs, glasswork, and coatings

缺点:

❌ Slow for deep cuts

❌ Manual calibration can be tricky

❌ Safety concerns – fully open-frame design

Who Is This For?

ComMarker Omni 1 isn’t for mass production or brute-force cutting. But for:

- Engineers

- Scientists

- Engraving artists

- Experimental makers

- Micro-manufacturers

…it’s a precision tool that unlocks things no other 激光雕刻机 in its price range can do.

ComMarker Omni 1 激光雕刻机

下一代激光解锁所有材料. ZeroBurn™ 雕刻技术 世界第一台 16K 高清激光雕刻机 10,000mm/s SpeedMax™ 雕刻系统 使用紫外激光解锁所有材料 ColdFront™ 热技术 电动升降 2 可选镜头兼容 EZCAD 和 LightBurn 360° 旋转雕刻系统

Want One?

查看 ComMarker Omni 1 and stay tuned for more advanced guides on:

- Focus calibration

- Advanced PCB prototyping

- Sub-surface glass modeling