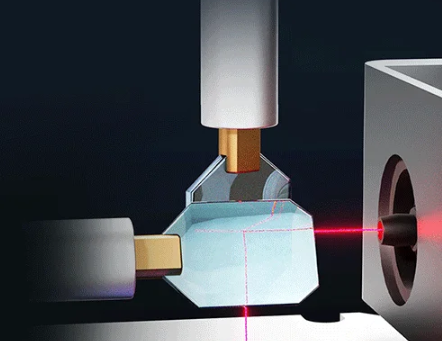

Glass engraving has traditionally been the domain of rotary tools and sandblasting, but with a fiber laser and a little prep work, 你可以实现酥脆, detailed etchings on glass surfaces—no special attachments required. 以下, we’ll walk you through a proven three-step process, originally shared by one of our customers, and show you how to adapt it to your 康马克 光纤激光雕刻机 for consistent, 高对比度结果.

Why Fiber Laser for Glass?

Most fiber lasers operate around 1064 纳米, a wavelength that glass does not absorb efficiently. 然而, by using a temporary marking layer, you can harness the pinpoint focus and high speeds of a fiber laser—like a ComMarker B6 JPT MOPA 或者 康马克泰坦 1—to leave a permanent, frosted design on your glass. The benefits:

- 精确: Micron-level focus yields sharp edges and fine details.

- 速度: Engrave in seconds—with speeds up to 15,000 mm/s on ComMarker machines.

- 多功能性: No need for rotary fixtures; flat glass, 瓶子, and vases all work.

- 耐用性: The final etch is permanent, weather-resistant, and dishwasher-safe.

What You’ll Need

- Glass item—anything from flat panels to wine bottles.

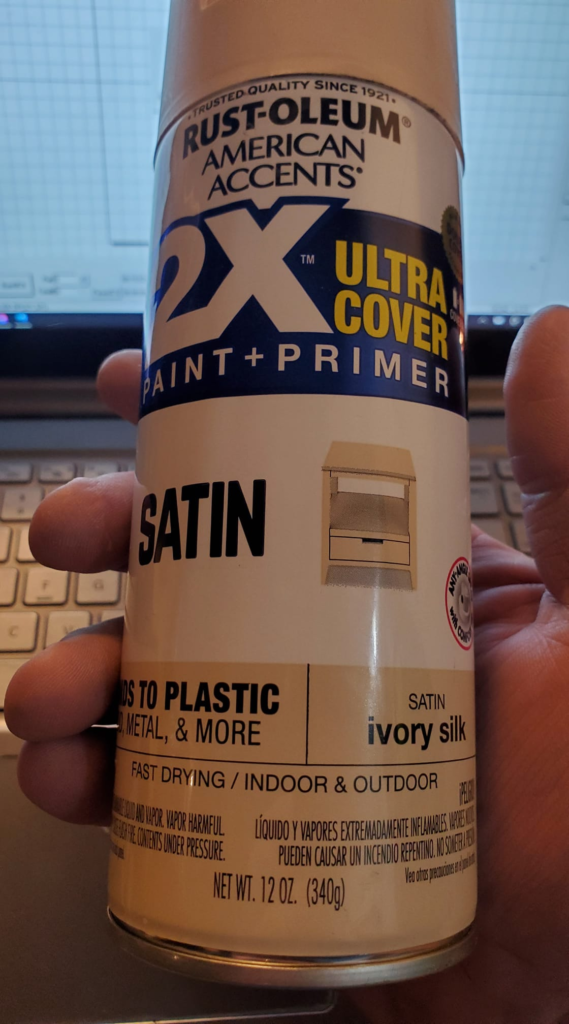

- Rust-Oleum 2X paint (Ivory Silk or flat white)—temporary marking layer.

- Paint sprayer or aerosol—for even coverage.

- Paint thinner—for post-engraving cleanup.

- ComMarker 光纤激光雕刻机—we recommend a 20 W+ unit with MOPA capability for optional color marking.

步 1: Prep & Paint Your Glass

- Clean thoroughly—remove oils, 指纹, and dust with isopropyl alcohol.

- Spray a thin, even coat of Rust-Oleum 2X Ivory Silk (or flat white) over your engraving surface.

- Hold can 8–12 inches away for a fine mist.

- Rotate bottles or move panels to avoid drips.

- Let it dry completely—at least 15–20 minutes in a dust-free area.

- Optional second coat if coverage is uneven.

Why Rust-Oleum? Its flat finish absorbs laser energy consistently, so you’ll get uniform etches without glaze or hotspots.

步 2: 激光设置 & 聚焦

With your glass painted and dry, it’s time to dial in your ComMarker settings:

| 范围 | Recommended Value |

|---|---|

| 激光功率 | 20–30 % (start low, then adjust) |

| 速度 | 10 毫米/秒 (for deep etch) |

| 频率 | 80 千赫 |

| 线间距 | 0.1 毫米 (100 微米) |

| 孵化模式 | 45° or “Crosshatch” for uniform fill |

| 通行证 | 1 (usually sufficient) |

- 自动对焦 your ComMarker head on the painted surface.

- Run a quick test on scrap glass or painted tile with a small circle to verify contrast.

- 调节功率 在 5 % increments if your etch is too shallow or too dark (risks chipping the paint).

步 3: 雕刻 & Clean Up

- 雕刻 your design—vector cut or bitmap hatch. The laser vaporizes the paint layer, exposing the frosted glass below.

- Wipe away the remaining paint with a lint-free cloth dampened in paint thinner or acetone.

- Rinse and dry the glass to remove any residue.

结果? A crisp white frosted design that’s fully bonded into the glass surface.

Pro Tips for Spectacular Results

- Keep it thin: Thick paint layers can lead to uneven etching or flaking.

- Mind the edges: Avoid painting over curved or lip areas—focus on the flat center for best focus.

- Test small: Always run a 10 × 10 mm test square to fine-tune settings before your final piece.

- Use MOPA: 如果你有一个 康马克泰坦 1, try longer pulse widths for subtle color shifts (grey, 青铜) on clear glass.

- Safety first: Wear laser-safe goggles and ensure proper ventilation when using solvents.

Why Choose ComMarker for Glass Engraving?

- Reliable MOPA Laser Modules (20 W – 200 w) designed for industrial uptime.

- Precision Optics that maintain focus across wide engraving fields.

- 用户友好的软件: LightBurn and EZCad2 compatibility for seamless file prep.

- 安全 & 支持: Enclosed Class 1 设计, responsive tech support, and robust training materials.

Whether you’re a hobbyist decorating shot glasses or a pro-shop offering high-end engraved trophies, 康马克 fiber lasers unlock glass engraving like never before. Ready to elevate your creativity? Explore our full lineup of fiber laser engravers and start etching memories in glass today!