When I first decided to build my own pinball machine, I thought, “Why not do it all myself?” From the circuit design to the glowing lights, I wanted it to be 100% handmade—and that meant using my gravator cu laser to make it happen.

În această postare, I’ll walk you through how I used my gravator laser cu fibra to design and fabricate custom PCB boards, how I handled the lighting system, and how laser technology gave me the precision I needed for such a detailed project.

Why I Used a Laser Engraver for My DIY Pinball Project

Sigur, you could order prefab circuit boards or outsource engraving, but if you’ve ever worked with a gravator cu laser, you’ll know the magic of having total control over your design. Am folosit ComMarker B6 60W MOPA fiber laser, which gave me sharp, precise lines for my PCB layout.

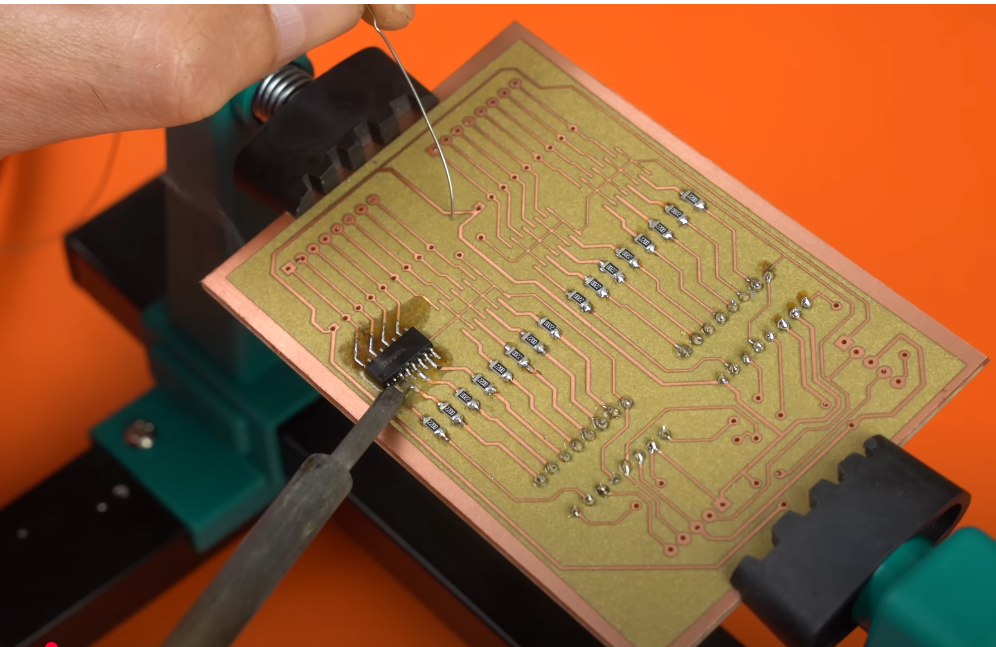

The laser engraver made it easy to etch my PCB patterns directly onto copper-clad boards, even without using a double-sided layout. And even though I didn’t have a CNC for drilling at the time, I managed the holes by hand—and the results were surprisingly clean.

💡 Sfat: For delicate electronics like PCB patterns, use lower power and higher speeds to avoid damaging the copper layer.

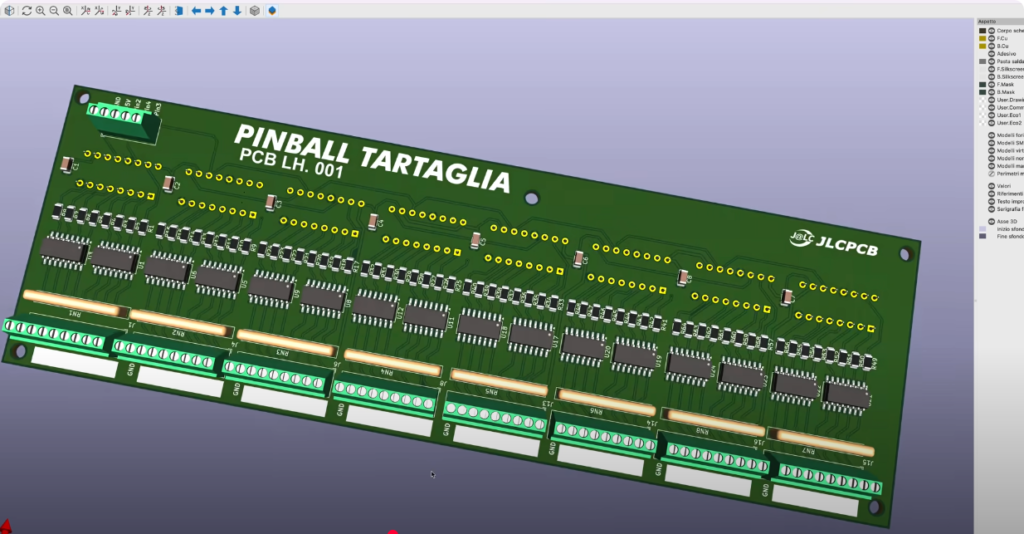

From Schematics to Reality – Designing My Light Control Board

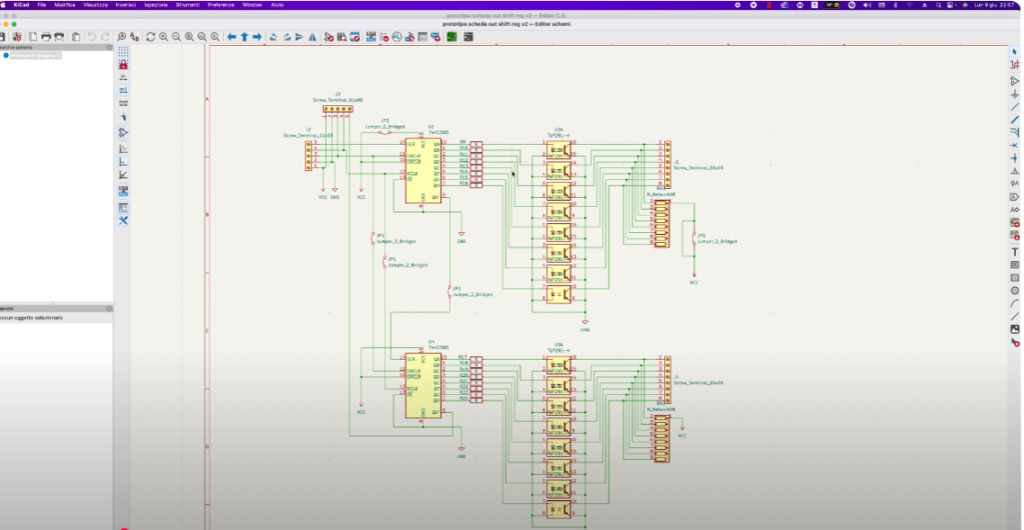

I started with a simple setup: two 74HC595 shift registers driving 16 outputs through opto-isolators. This board controls the programmable lights on the pinball machine. Using my gravator cu laser, I marked the tracks and component positions directly onto the blank PCB.

Even with tight spaces between traces, the laser engraving gave me sharp boundaries and consistent depth. I placed the chips in reverse to avoid crossing traces unnecessarily—just another little tweak you can test when you have your own gravator cu laser at home.

🛠️ Recommended Gear: If you’re doing similar work, make sure your laser has a spot size under 0.05mm for fine details.

Real Talk: Engraving vs. Drilling

Here’s the thing—a laser engraver isn’t a drill. Sigur, it can mark your drilling points, but unless you’re using a hybrid CNC-laser combo, you’ll still need to do mechanical drilling.

Acestea fiind spuse, I saved hours of layout time by using the laser to test and revise my PCB layout. The laser also helped me debug the circuit—by marking visible traces, it was easier to test continuity with a multimeter.

✅ Pentru vârf: Use your laser engraver to prototype boards before committing to full production—especially for one-off or experimental designs.

Assembling the Components – One Solder at a Time

Once the board was engraved, it was time to assemble. I soldered 220-ohm resistors, TLP281 opto-isolators, and all the IC sockets by hand. da, even with a baby trying to crawl onto the table—parenthood and pinball builds can coexist!

And here’s where my gravator cu laser came in clutch again: I added reference text and component outlines directly on the board. No stickers, no markers—just clean, durable markings that won’t rub off.

✍️ Why It Matters: Laser-engraved labels on your PCB eliminate guesswork when assembling or troubleshooting later.

Why Laser Engraving Beats Silkscreen for DIY Boards

Let’s talk benefits. Compared to traditional silkscreen printing, A gravator cu laser:

- Doesn’t require chemical processing

- Offers real-time design edits

- Gives high-contrast, high-durability markings

- Works on various materials—FR4, cupru, aluminiu anodizat, and even wood

And if you’re only doing a few prototypes, it’s just not worth sending the design to a fab house. Laser engraving lets you stay flexible, make mistakes, and iterate fast.

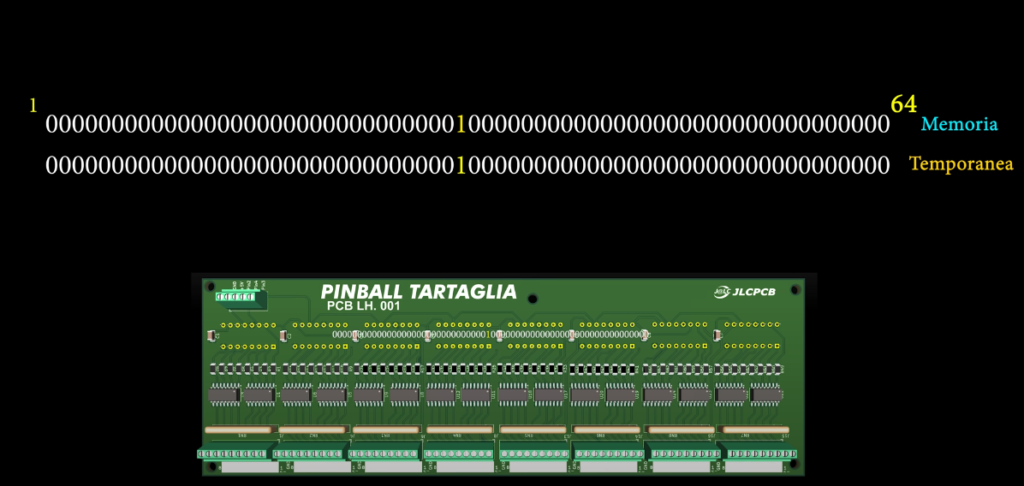

Lighting Up the Build – One Bit at a Time

Controlling the lights was the fun part. I used a 64-bit memory system controlled by Arduino, with each bit representing a light state. By toggling bits in memory and sending them through shift registers, I could control which lights were on.

The key here is low-latency communication—and having an engraved layout helped ensure wiring was clean and traceable. Din nou, this is where laser engraving helped my design stay compact and reliable.

🧠 Bonus: If you’re planning a light-based project (like cosplay, robotics, or even interactive art), laser-engraved boards can really streamline your workflow.

What I Learned from Using a Laser Engraver for Electronics

Folosind a gravator cu laser for this project taught me a lot:

- Precision beats speed. Slower passes gave me cleaner lines, especially on copper.

- Test first. Do a test burn before committing your final board.

- Laser engraving isn’t just decoration—it’s functionality. When you engrave traces, etichete, and outlines, you’re setting yourself up for an easier build process.

If you’re a maker or DIYer wondering whether a gravator cu laser is worth the investment—this project is proof that it absolutely is.

Gravura laser cu fibre ComMarker B6

Laser oriunde. Precis dar inteligent. Dimensiune compactă record 2-in-1 Design tehnologie auto-focalizare 15.000mm/s Speedmax ™ Gravură 8K HD Precizie inteligentă LED TOUCH ECRAPA CLASE COLDFRONT ™ Tehnologie termică 1 Masina cu laser de siguranta

Should You Use a Laser Engraver for Your DIY Builds?

Absolutely yes.

Whether you’re making PCBs, custom control panels, or just adding flair to your 3D-printed projects, A gravator cu laser opens up new levels of creativity. It gives you professional-level results at a hobbyist price—and makes the whole process way more fun.

And trust me—once you engrave your first working PCB or backlit acrylic panel, you’ll never go back.

Ready to start your laser engraving journey?

Vezi ComMarker B6 sau Omni 1 Laser UV for powerful, precise machines perfect for electronics, hobby builds, și altele.